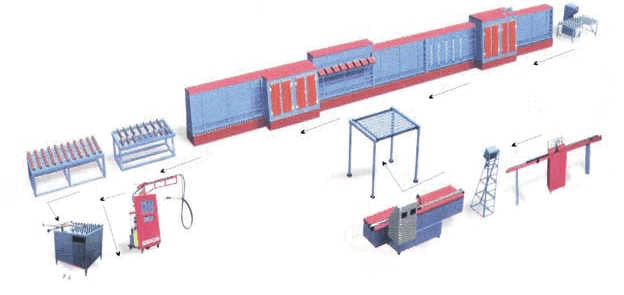

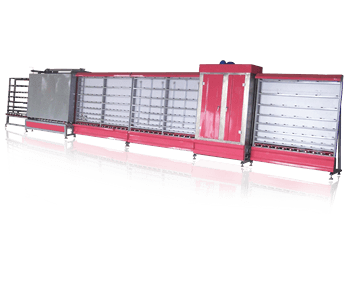

GLASS INSULATING

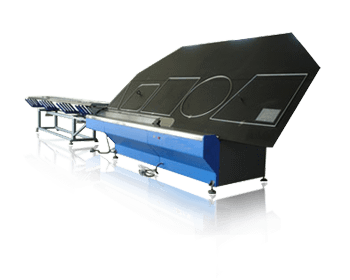

Glass Insulating with Aluminium Spacer Bar

- Include Glass Washing, Drying, Assembly & Pressing

- Glass Thoroughly Washed & Dried Prior to Assembly

- Perfect Alignment of Top & Bottom Glass

- Available in Vertical Panel Press, Vertical Roller Press & Horizontal Roller Press

- Available from High Performance Models till Budget Models

- Available from 1200mm till 2500mm

Spacer Bar Shape Bending Machine

- Bend Linear Spacer Bars into Spacer Frames

- Bend Spacers with Various Thickness

- Fast & Efficient

- Reduce Extensive Labor Force

- Cutting Spacer is also Possible

- Available in Two Models, Fully Automatic & Semi-Automatic

- Fully Automatic Model Comes with Automatic Spacer Feeding Magazine

Spacer Bar Curve Bending Machine

- Bend Linear Spacer Bars in Curve Shape

- Radius of Curvature is Adjustable

- Almost Free of Maintenance

- Available in Two Models, Electrical Motorized Driven & Hand Wheel Driven

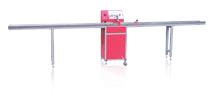

Spacer Bar Cutting Machine

- Cuts Spacer Bar In Exact Lengths Less Than A Second

- Advance Cutting Design Eliminates Unwanted Burrs & Chips

- Special Design Rotating Cutting Disc

- Come With Sliding Gauge Measuring Ruler & Stoppers

Desiccant Filling Machine for Bend Spacer

- Available in Two Models, Fully Automatic & Semi-Automatic

- Fully Automatic Model Drills Holes, Dispenses Salt & Seals Holes

- Semi-Automatic Does All Process Except Hole Seal

- Sophisticated Machines with Latest Technology

- Molecular Sieves Feeding Pneumatically

- Vibrating System Ensures Adequate Salt Filling

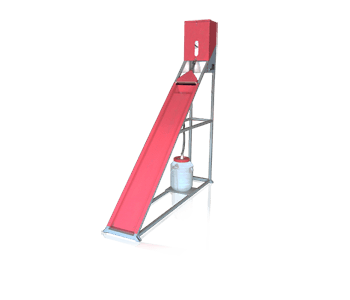

Desiccant Filling Machine for Straight Spacer

- Available in Two Models, Gravity & Vibrating

- Simple Structure

- Easy Operation

- Almost Maintenance Free

- Molecular Sieves Reservoir

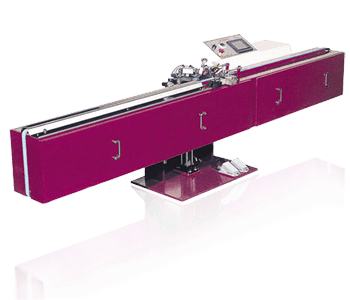

Butyl Extruding Machine

- Design for Insulated Glass Primary Seal

- PLC Control

- Consistent Butyl Extrusion Free of Bubbles

- Pump with Powerful Hydraulic System

- Adjustable Conveying Speed

- Apply also on Curve Spacer Bars

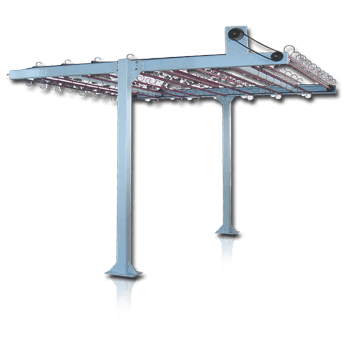

Overhead Hanging Conveyor For Spacer Frame

- Usually Put between IGU PVB Assembly Line & Butyl Extruder

- Spacer Frames Hung Overhead after Butyl Extrusion

- Keeps Frames Non-Sticky & Dimensionally Non-Distorted Prior to IG Assembly

- Electrically Motorized System Conveys Frames Towards IG PVB Assembly Line

- Easy Spacer Frames Loading & Unloading

- Also Storage of Spacer Frames

Two Parts Sealant Extruding Machine

- Secondary or Final Sealing of Insulated Glass

- Suitable for Polysulfide, Polyurethane & Silicon

- Pneumatic & Hydraulic Pumping Systems

- Precision Metering & Mixing Design

- Exact Mixing Ratio between Components A & B

- Sophisticated Gun & Nozzle

Rotating Table for Sealing Application

- Accessory Equipment for Secondary Seal or Hot Melt Application

- Turn Table Design

- Vacuum Suction Cups Hold Glass in Position

- Rotates Continuously or Step by Step

- Extension Arms Hold Large Glass

Low-E Glass Edge Deletion Tool & Machine

- Remove Low-E Coating of Glass Edges

- Powerful Spindle

- Delete Coating Thoroughly

- Available in Two Models, Handheld Tool & Semi-Automatic Machine

- Deletion Tool Powered by Pneumatic & Uses No Electricity

Inert Gas Filling System

- Fill Inert Gas for Insulated Glass

- Fill Argon, Krypton or Any Other Inert Gas

- Reduce Thermal Conductivity & Noise

- Operate Either Inert Gas Concentration or Gas Filling Time

- Available in Two Models, Portable & Cabinet

- 3 & 6 Outputs

Inert Gas Detecting Apparatus

- Handheld compact design suitable for onsite operation

- Detect if Argon Gas Filled Inside IG Unit

- Precision probe sensor ensures proper checking

- Non-Invasive Technology

- Non-Destructive Testing

- Allows 100% quality control

Insulated Glass Production Line with Rubber Spacer Strip

- Single Seal Insulating Process without Primary Butyl Seal

- Lower Capital Investment of Production Machines

- Occupy Little Space

- Simpler Production Process.

- Produces also Curve & Bend Insulated Glass

Hot Melt Butyl Extruding Machine

- Single Seal Insulating Process without Primary Butyl Seal

- Available in Extruders with Single Gun & Double Guns

- UP to 200kg Butyl Cavity

- No Sealing Mixing Required

- No Complicated Pumping System

Press Table for IGU Sealing

- Applicable for Single Seal Or Dual Seals IG Units

- Ball Caster Metal Structure

- A Pair of Flat Bar Opens or Closes Pneumatically

- Speeds Up Sealing at Least Labor Force

Molecular Sieves Desiccant

- Dry Water Moisture & Keep Air From Humid

- Extremely High Water Absorbing Ability with Low Dust Index

- Holds & Locks Moisture & Never Releases

- Ingredients To Make Rubber Spacer Bar

- Packing Available from 25kg to 500kg

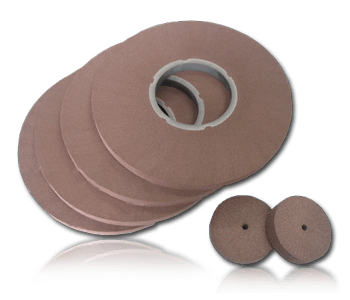

Low-E Glass Edge Deletion & De-Coating Wheel

- Remove Low-E Coatings on Glass Surface

- Tough To Remove Coating but Leaves no Marks on Glass

- Available in Various Sizes for Automatic & Semi-Automatic Machines & Handheld Tools

PS, SI, PIB Butyl, Hot Melt Sealants

- Two Parts or Single Part Polysulphide & Silicon

- Primary & Secondary IG Sealant Available

- Structural Silicon for Total Glazing

- Butyl Excellent In Moisture & Gas Vapor Transmission Proof

- Re-Usable Hot Melt Sealant

- Fast Cure Sealants

- Compatible To All Types of Extruding Machines

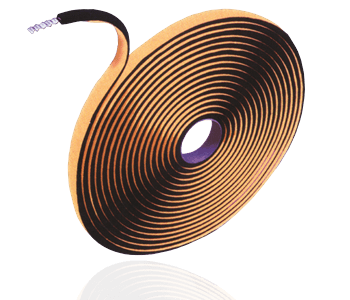

Butyl Adhesive Tape for Primary Seal

- Substitution of Conventional Butyl Block

- Thin Layer of Butyl Sealant Pre-Extruder In Tape

- No Butyl Extruding Machine Is Required

- Applicable with Simple Tools

- Lowest Possible IG Production Costs

- Perfect Water & Vapor Permeable Proof

Rubber Spacer Strip For Insulating Glass Unit

- Single Sealed Polymer Based Warm Edge Rubber Strip

- Perfect Substitution to Aluminum Spacer

- Contains Desiccant

- Require No Butyl & No Two Parts Components Extruder

- Soft & Flexible to Bend into Curve & Shape IG

- No Corner Keys & No Straight Connectors Are Required

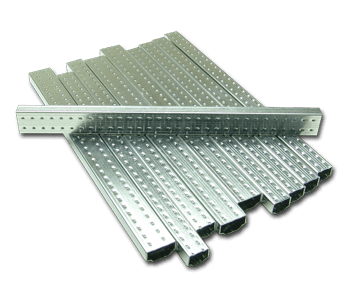

Aluminium Spacer Bars

- Excellent Thermal Barrier

- Consistent Width & Height Along Length

- Suitable for Angle or Curve Bending with Automatic Spacer Bending Machines

- Uniform Holes Punching Allows Best Water Absorption with Desiccant

- Free of Scrap & Oil

- Available in Various Sizes

- Available with Standard & Gas Fill Plastic Corner Keys & Straight Steel Connectors

Plastic Connectors for Spacer Bars Connection

- Made From the Most Durable Plastic

- Special Design Fins for Easy Insert into Spacer Bars but Very Difficult to Remove

- Stiff Enough to Hold Aluminum Frame in a Rigid Body

- Corner Keys with Holes & Plug Available for IG Inert Gas Dispensing

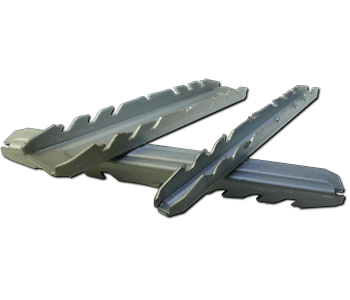

Steel Connectors for Spacer Bar Connection

- Made From the Finest Rust Proof & Anti-Corrosive Steel

- Precision Sizes Just Fit into Spacer Bars

- Easy Insert into Spacer Bar but Difficult to Remove

- Extremely Stiff Holding Joint Spacer Bar Firmly in Place

- Leak-Proof of Tiny Molecular Sieves

- Very Suitable for Automatic Spacer Bar Bending Machine

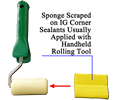

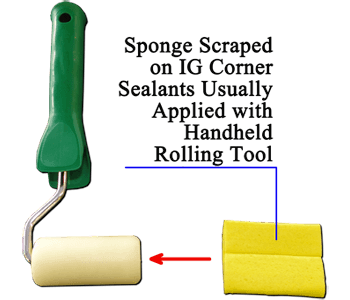

IG Corners Sealant Scraping Sponge

- Sponge Specially Designed for IG Sealant Corner Scraping

- Non-Sticky with Popular IG Sealants Including Polysulphide, Polyurethane, Silicon & Butyl

- Turn Flabby Corner Sealants Solid & Nice Looking

- Easy to Fit into Handheld Rolling Tool but Anti-Slip During Roll Over Sealant

- Take Only Seconds to Handle an IGU Sealant Corner

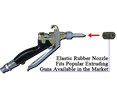

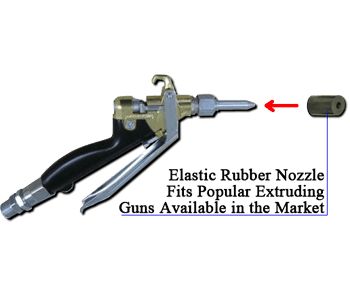

Rubber Nozzles for Sealant Extruding Gun

- Rubber Nozzles Specially Designed & Produced for Extruding Guns of IG Sealant Extruding Machines

- Durable High Quality Rubber

- Slope Nozzle Surface Get in Contact Along Glass Edge Smoothly

- Elastic Rubber Fits into Extruding Gun Head Easily

- Proper Hardness of Rubber Holds Firmly at Extruding Gun Heads

- Suitable for Extruding Guns of Popular Extruding Machines Available in the Market

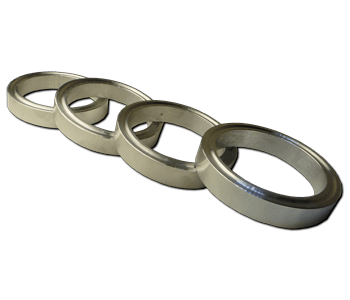

Aluminum Spacer Rings for Spider IG Facade

- Design for Spider Joint Glass Insulating Façade

- Made of High Quality Aluminium Alloy

- Excellent Dimensional Finish Guarantees Consistent Space Between Two Pieces of Glass

- Carefully Surface Finish Compatible to IG Sealants

The Most Comprehensive Selected Top Class Chinese Glass Machines, Products and Services Resource

The Most Comprehensive Selected Top Class Chinese Glass Machines, Products and Services Resource

Glass Fabricating Machines | Glass Processing Machines | Glass Furnaces | Glass Ovens | Glass Manufacturing & Production Equipments | Glass Accessories | Glass Toolings | Glass Supplies | Glass Consumables | Glass & Mirror | Glass Engineering | Glass Contracting | Glass Consulting | Glass Services- Contact Us | Terms of Use Copyright © 1989 - 2020 Xinology Co., Ltd. All Rights Reserved.