Features & Specs

Interlink Ribbon & Busbar Processing

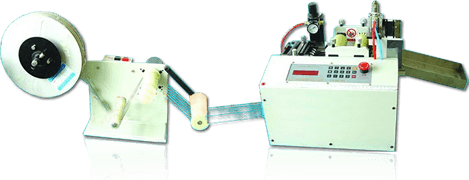

Ribbon & Busbar Cutting Machine

Strip ribbon and busbar usually come in reel and roll form. This cutting machine is used to cut ribbon strip and busbar into requested length.

| Ribbon & Busbar Materials | Tin & Copper Alloy |

| Cutting Speed | 8 ~ 11kg/hr |

| Max. Cutting Length | 10 m |

| Cutting Accuracy | ± 0.2 mm |

| Outer Dimension (LxWxH) | 700 x 400 x 700 mm |

Ribbon & Busbar Cutting & Bending Machine

This machine is used to cut strip and busbar into requested length. It also bends ribbon at requested distance.

| Ribbon & Busbar Materials | Tin & Copper Alloy |

| Ribbon Width | 1 ~ 8 mm |

| Cutting Speed | 8 ~ 11 kg/hr |

| Max. Cutting Length | 10 m |

| Max. Bending Deviation | 0.5 mm |

| Cutting Accuracy | ± 0.2 mm |

| Voltage | 220VAC / 50Hz |

| Power | 180 W |

| Weight | 30 kg |

| Outer Dimension (LxWxH) | 400 x 300 x 270 mm |

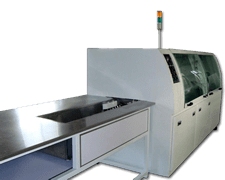

Ribbon & Busbar Drying Machine

- After cutting, ribbon and busbar are soak in liquid agent which helps subsequent soldering.

- This drying machine dries ribbon and busbar thoroughly after soaking by means of infra red lamps.

- Semi- and fully automatic machines are available.

- Ribbons and busbars are put and dried inside cylindrical baskets.

| Automation | Semi-Automatic | Fully Automatic |

| Production Type | Batch | Continuous |

| Air Quantity Control | Infinite | Infinite |

| Main Motor Speed Regulation | Infinite | Infinite |

| Infra Red Heater | 220VDC/300W * 6 | 220VAC/80W * 18 |

| Voltage | 220 VDC | 380VAC / 3 phase / 50Hz / 4 Wires |

| Power | 1.8 KW | 15 KW |

| Weight | 50 kg | 800 kg |

| Outer Dimension (LxWxH) | 600 x 300 x 600 mm | 3180 x 1180 x 1580 mm |