Features

- Introduction

- Entrance Conveyor

- Washing and Drying Machine

- Inspection, Registration and Assembly Conveyors

- Lifting System with Vacuum Suction Cups

- Transition Buffer Conveyor

- Heating Ovens and Rollers Presses

- Exit Conveyor

- Electrical Control Console

- Tiltable Glass Loading Table (optional)

- Oscillating Cup Brushes Scrubbing Section (optional)

- Rotary PVB Rack (optional)

- Tiltable Glass Unloading Table (optional)

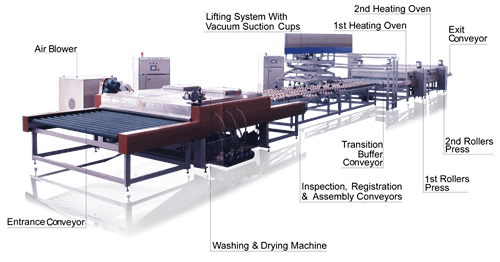

Introduction

Sophisticated FLG Glass Laminating Line Is Built With Carefully Selected Components By First Class Workmanship

This flat laminated glass production line is used to wash and dry glass, sandwich interlayer film (mostly PVB) in between two pieces of glass (or more), pre-laminate by means of roller pressing and heating. This line is specially designed to make flat laminated glass, armor glass, bulletproof glass, burglary proof glass and anti-theft glass, etc.

This production line includes,

- Entrance Conveyor

- Horizontal Glass Washing and Drying Machine

- Inspection, Registration and Assembly Conveyors

- Lifting System with Vacuum Suction Cups

- Transition Buffer Conveyor

- Heating Ovens and Rollers Presses

- Exit Conveyor

- Electrical Control Console

Options:

- Tiltable Glass Loading Table

- Oscillating Cup Brushes Scrubbing Section

- Rotary PVB Rack

- Tiltable Glass Unloading Table