Features

- Introduction

- Entrance Conveyor

- Washing and Drying Machine

- Inspection, Registration and Assembly Conveyors

- Lifting System with Vacuum Suction Cups

- Transition Buffer Conveyor

- Heating Ovens and Rollers Presses

- Exit Conveyor

- Electrical Control Console

- Tiltable Glass Loading Table (optional)

- Oscillating Cup Brushes Scrubbing Section (optional)

- Rotary PVB Rack (optional)

- Tiltable Glass Unloading Table (optional)

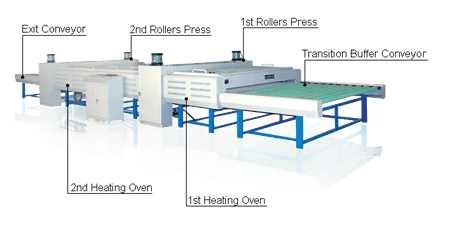

Heating Ovens and Rollers Presses

This part is composed of pre-heating oven, 1st roller press, heating oven, 2nd roller press, exit conveyor and electrical control cabinet.

Pre-Heating Oven

- It is built with tubular steel and is suitably treated and painted.

- Conveying rollers are galvanized steel tube.

- The heating lamps are infra red (IR) quartz tubes which are more effective.

- The oven is covered by steel with double layers of heat insulation materials. The first layer is special heat insulation material which drastically reduces temperature. The second layer insulation material is a further heat barrier and meanwhile, acts as supporters to the first insulation layer. There is stainless steel plate in the inner side of the furnace casing. This plate is used for reflection of infra red IR irradiation and meanwhile, full protection of insulation materials.

- The conveyor rollers are covered by heat resistant material so that the hot glass would not burn the rollers. The temperature is controlled automatically. The conveyor is driven by speed adjustable motor.

1st Roller Press

- This press is composed of one top and one bottom press rollers. Each of rollers is made of cylindrical steel with surface covered by heat proof rubber. These rollers are placed on sturdy steel structure and are supported by two heavy duty bearings.

- There are pneumatic cylinders on both sides of the steel presser. They are used to exert necessary pressure when well-assembled glass passes in between top and bottom press rollers. While laminated glass is passing through the roller press, air in between PVB and glass is expel.

- Meanwhile, PVB wrinkles, if any, are eliminated and would not be recovered even the exert pressure is released when glass comes out from the presser.

- Top and bottom rollers distance is adjustable according to glass thickness.

Heating Oven

- This oven is similar to the pre-heating oven but is longer.

- The temperature in this oven is slightly higher than the pre-heating oven.

- The higher temperature is used to melt the interlayer film thoroughly so that the subsequent roller press is capable to seal the glass edges.

2nd Roller Press

- The structure of this press is identical to the 1st roller press.

- After passing this 2nd roller, glass edges are well-sealed by PVB bonding to prevent air from entering during subsequent process.