Features

Structure

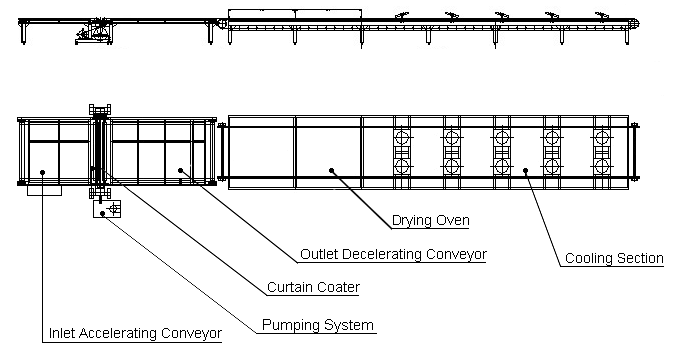

Layout

Acceleration Conveyor

This inlet is a belt conveyor design. This reinforced belt made of special durable rubber. Acceleration is controlled by frequency converter. Precision control system provides quick and accurate regulation of acceleration speed. A guiding system is equipped to avoid mirror or glass traveling in deviated path.

Mirror or glass enters into the belt at constant speed. When majority of front leading part of mirror or glass are on the belt, it is accelerated to required speed instantly passing through subsequent curtain coater. The faster the acceleration, the thinner is the paint layer. When thicker paint layer is required, lower acceleration is regulated. After mirror or glass leaves completely off of belt conveyor, it automatically returns back to constant speed and waiting for next mirror or glass.

Curtain Coater

General

It is a standalone machine locating in between inlet and outlet conveyors. It is composed of curtain coating head, paint collecting tank, pumping system, filtering system and plumbing.

Curtain Coating Head

It is a bridge designed flat steel structure across glass traveling direction. The coating head is made of two special steel plates aligned in V shape with flat narrow opening. Paint is kept and maintained at certain level inside this V shape paint reservoir. Paint falls down passing through flat narrow opening by means of gravity. Paint falling is kept running all the time even though there is no mirror or glass loading during operating hours.

When mirror or glass is accelerating and passing through paint curtain, mirror or glass "cuts" the paint curtain. Thin layer of paint is then coated from mirror leading edge till tail edge. Steel plates opening width is adjustable. If thinner paint layer is required, narrow the opening. If thicker paint layer is required, widen the opening.

Paint Collector

When there is no mirror or glass passing underneath coating head, falling paint goes to a paint collector located beneath coating head. When there is mirror or glass passing underneath coating head, excessive paint flows over to paint collector along two sides of glass or mirror.

Pumping & Filtering Systems

It is a submersible pump dipping inside paint drum (to be provided by buyer). Pump motor is explosive proof. Paint flow amount is adjustable by valve. The larger the flow amount, the thicker is paint layer and vice versa. Paint is pumped up to coating head reservoir through a filtering system. This closed loop circulating system minimizes paint wastage.

Deceleration Conveyor

This structure is similar to inlet accelerating conveyor. Instead of acceleration, this belt conveyor is used to decelerate mirror or glass. Deceleration is controlled by frequency converter. Precision control system provides quick and accurate regulation of deceleration speed. A guiding system is equipped to avoid mirror or glass traveling in deviated path.

When mirror or glass is passing Glass & Mirror Curtain Coating Machine at high speed, this outlet conveyor is also synchronize and running at identity acceleration speed. When all mirror or glass arrives at this belt conveyor, it decelerates to required constant speed instantly. After mirror or glass leaves completely off of this belt conveyor, the belt stills travels in same constant speed until subsequent mirror accelerates through coating machine.

Buffer Conveyor

It is a roller structure located in between upstream outlet conveyor and downstream drying oven. Mirror may not travel in same speeds at outlet conveyor and drying oven, this buffing area allows mirror queuing management right before drying oven. This buffer area is especially helpful if mirror is extra long or mirror travels at lower constant speed in drying oven than that in decelerating conveyor.

Drying Oven

This baking oven is an enclosure structure consisting of slats or rollers conveyor, heating resistors and exhaust fans above conveyor. Conveying speed is adjustable. Heaters bake and to remove paint solvent. Vaporized solvent is evacuated by exhaust fans. Exhaust pipes are provided up to certain height. Extra piping to direct vapor out of workshop is to be provided by buyer.

Cooing Section

Cooling fans are equipped in this enclosure structure with rollers conveyor. Conveying speed is adjustable. Mirror paint is then cooled down until it is good enough for handling.

Control System

All controls are accessed from this standalone control console.