Features & Spec

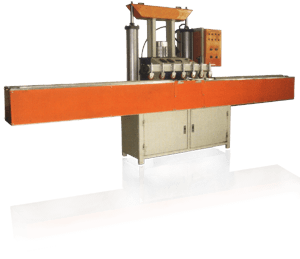

IG-HM-DS

Introduction

Both Primary & Secondary Seals Are Made At One Time By IG-HM-DS Dual Seal Hot Melt Extruding Machine

IG-HM-DS is a very special hot melt extruding machine to make dual seal insulated glass. Hot melt is applied on three sides of aluminium spacer bar at one time. In additional to traditional single seal hot melt double glazing, primary seal is also applied with hot melt butyl by this unique machine.

Structure

Extruder

It is an extruder similar to a traditional hot melt butyl extruder. It melts and extrudes hot melt butyl.

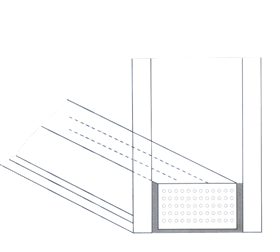

Sealing Nozzles

Nozzles applied both primary and secondary seal on three sides of aluminium spacer bar at one time.

Conveyor

It runs on a working table where spacer bars are driven during extrusion.

Rollers Press

There are several press rollers above conveyor. They hold spacer bars in position and keep them running in right track during extrusion.

Operation

- Four pieces of spacer bar are pre-connected end to end with foldable connectors which could be folded into right angle instantly.

- The well connected linear spacer bars are loaded on conveyor when it is running. Conveyor drives spacer bars underneath press rollers which hold them in position and keep them running in right track. When spacer bars arrive at sealing nozzles, three sides of aluminum spacer bar are applied by hot melt automatically. Inner side of spacer is free of hot melt.

- When first piece of spacer bar is coated with hot melt and exit out from press rollers, operator folds it up. When second piece of spacer bar is coated with hot melt and exit out from press rollers, operator folds it up again. This is repeated until linear spacer bars becomes a frame structure. The last corner is then finally joined with foldable connector by operator.

- This hot melt butyl coated frame is then passed to subsequent assembly process.

Specifications

| Model | IG-HM-DS | |

| Speed | 15 m / min. | |

| Hot Melt Butyl Consumption | 6 mm spacer | 25 g/m |

| 9 mm spacer | 30 g/m | |

| 12 mm spacer | 38 g/m | |

| Production Capacity | 1000 ~ 1200 DGU / 8 hrs (base on 1 x 1 m glass with skilful operator) |

|

| Compress Air | 0.05 m3 / min. at 0.5 MPa | |

| Power | 16 KW | |

| Voltage | 380V / 3 Phases / 50Hz | |

| Weight | 150 kg | |

| Outer Dimension | 4000(L) x 500(W) x 1600(H) mm | |