Features

- Low-E Glass Washing

- Tilting Unloading Table

Low-E Glass Washing

- The last cylindrical brush is substituted with fine soft Nylon bristles. All other cylindrical brushes remain unchanged.

- All other cylindrical brushes would lift up during low-e glass washing to avoid hard brush from scratching low-e coating.

- A low-e coating detector is equipped. When glass is low-e, the detector would send a signal to lift up hard brush. If low-e glass is incorrectly loaded with coating surface facing leaning rollers, detector would send signal to stop the machine.

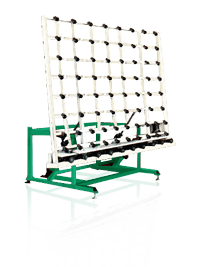

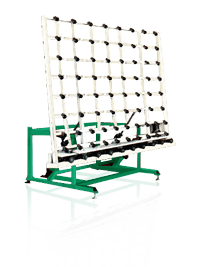

Tilting Unloading Table

- This table is a substitution of exit conveyor.

- It is a metal structure with freely moved caster balls. It could be tilted from vertical to horizontal or vice versa pneumatically.

- Insulated glass exits from rollers press and arrives at this table when it is in vertical position. After inspection, table is tilted horizontally. Semi-finished insulated glass is unloaded for subsequent secondary or final seal. It is then tilted up vertically and is ready to accept next glass.