Features

Structure

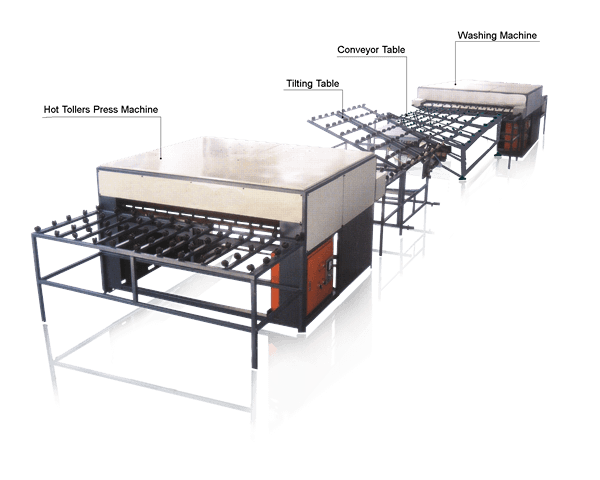

Washing Machine

It is a horizontal glass washing machine with entry table, two pairs of cylindrical brushes, one water tank, one pair of sponge roller, one blower with a pair of air knife and exit table. A motorized mechanism is used to drive all cylindrical rollers all the way from washing section till drying section.

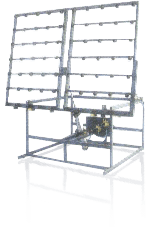

Tilting Table

This is the table where two glass panes are assembled together separated with spacer frame. It is a ball caster structure with welded tubular metal. It is divided into two parts. The lower part is a fix metal structure. Upper part is a tiltable structure with many idle caster balls. It is strongly hinged to lower part allowing safety glass tilting. A pneumatic system is used to tilt the ball castor table.

Rollers Press

It is used to press the double glazing unit for primary seal. It is a cylindrical roller conveying structure machine. It consists of three sections, entry table, rollers pressing section and exit table. In pressing section, there is a pair of press roller. One is on top and another bottom. Heavy duty press rollers are strong enough to exert necessary pressure to seal insulated glass. Meanwhile, press roller is specially treated such that it is elastic enough not to break the glass.