Features

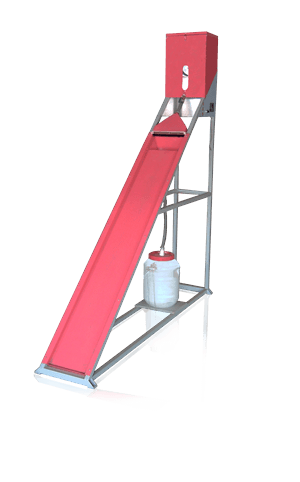

IG-DF-V

IG-DF-V is an upgraded model modified base on IG-DF-G gravity filling machine

with additional vibrating and heating system

Vibrating System

Vibration system ensures molecular sieves are tightly piled up inside spacer bars. It makes sure spacer bars filled with adequate amount of molecular sieves sufficient enough to dry air inside insulated glass.

Heating System

Heating system is used to keep desiccant dry. It guarantees desiccant free of moisture before loading. This extends desiccant storage time and thus, allows large quantity of molecular sieves stored in reservoir and meanwhile, prevents it from wet. This design also eliminates frequent desiccant re-filling and thus, reduces downtime.

Easy Operation

Adequate amount of desiccant is filled inside reservoir. It passes into underneath desiccant hopper and is stopped by brushes block. Several pieces of spacer bars are inserted into desiccant hopper through brushes block. By means of vibration, desiccant finds its way down and is almost forced to fill up spacer bars. When spacer bars are fully loaded with desiccant, vibration is stopped. Spacer bars are removed from desiccant hopper. Elastic brushes blocking plate is recovered to prevent desiccant from falling down.

Recycling Drum

On sliding board, there is an exit right beneath desiccant hopper. The exit runs to desiccant recycling drum located underneath the sliding board through a hose. Excessive desiccant will be collected in the drum during filling.