Features

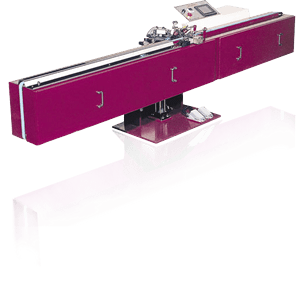

IG-BE-A

Introduction

IG-BE butyl extruding machine is used to melt, extrude and applied strings of butyl sealant along two sides of straight and curve spacer bars. Nozzle distance is regulated automatically according to spacer bar's thickness. Spacers could be any rigid materials, for example, aluminum, steel, stainless steel or reinforced plastic.

Structure

Belt Conveying Table

This table could be raised up or lower down. A belt conveyor runs from one end to other end of the table. Spacer bars are well connected filled with desiccants. This spacer frame is loaded on belt conveyor while it is running. Belt conveying speed is adjustable according to requirement. When speed is changed, extruded butyl amount is changed automatically. This guarantees adequate amount of butyl is applied on spacer bar irrespective belt conveyor speed.

Melting System

Precision temperature control ensures butyl is thoroughly and consistent melted at proper temperature during extrusion.

Pressure System

Hydraulic and pneumatic dual pressurize system guarantees consistent and continuous butyl extrusion.

Extruding Nozzles

There are two sophisticated extruding nozzles placing in “V’ shape right next to the conveyor belt. One nozzle is on one side of the belt while another is on the other side. While spacer bar is running in between the two nozzles, continuous and consistent amounts of butyl are applied on both sides of spacer bar. Nozzles distance is automatically adjusted according to spacers’ width. No manual adjustment is required.

Control System

It is a PLC system with touch panel HMI human machine interface. All controls such as butyl extruded amount and melting temperature are adjusted here. When it is run out of butyl, it alarms.

Butyl Loading

Two butyl packs could be loaded in the machine at the same time. This minimizes changeover time.