glass bending

Overview

- Bend Glass into Shapes by Heating with Bending Moulds

- Single & Multiple Glass Heating Stations

- Continuous Glass Bending Furnace for Mass Production

- Rotary Glass Bending Designed Saves Space

- Slumping Oven for Very Deep Bending Depth

- Full Cycle of Glass Heating, Annealing & Cooling

- Sophisticated Design Free of Glass Optical Distortion

- High Efficient Heat Resistors

- Thick Thermal Insulated Oven Walls for Heat Preservation

- Minimum Heat Loss with Lowest Possible Energy Consumption

- Various Bending Oven Designs Suitable for Any Glass Fabricators

Single Glass Bender

- Budget Bending Ovens for Medium Low Volume of Production

- Available in Versatile Oven Design

- Available in Single, Two or Three Stations

- Metal Structure with High Temperature Resistant Paint

- Wall Panel Covered with Thick Thermal Insulation Material

- Minimum Heat Loss with Lowest Possible Energy Consumption

- Thermocouples Measure Real Time Temperatures

- Design for Glass Deep Bending with Smallest Radius of Curvature

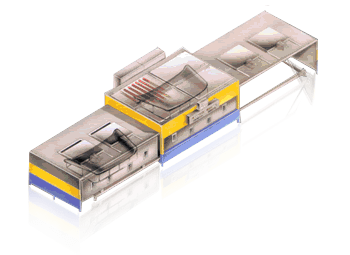

Multiple Glass Bender

- Serial Oven Design with Multiple Heating Station

- Two Storey Oven Design for High Volume Production

- Glass Heat & Bend in Upper Deck

- Glass Annealed & Cooled in Lower Deck

- Exhaust Heat in Lower Deck Recycled to Upper Deck Saves Energy

- PLC for Temperature Profile & Bending Wagon Movement

- Automatic Glass Bending, Annealing & Cooling

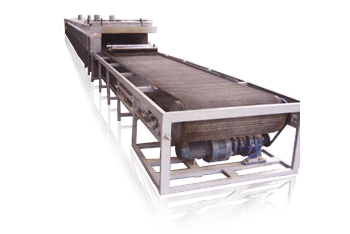

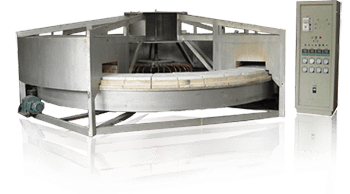

Continuous Glass Bender

- Belt Conveyor for Small Medium Glass Size

- High Volume Production

- Pre-Heat, Bend, Anneal & Cool done all the way

- Suitable for Glass Baking, Cooking, Decorating & Fusing

- PLC Controls Heating Profile & Conveyor Speed

Rotary Glass Bender

- Least Space Consumption for High Volume Production

- Glass Loading & Unloading at Same Station

- Suitable for Rear View & Cosmetic Mirrors Production

- Vacuum System for Large Bending Depth & Small Curvature

- Refractory Maximizes Heat Energy Preservation

- Marks & Scratches Free Top Quality Bending Moulds

Glass Slumper

- Chamber Design for Glass Slumping & Deep Bending

- Produces Glass Sink with or without Connected Glass Platform

- Slump Transparent Glass Basins Free of Marks & Scratches

- Available in Low, Medium & High Volume Productions

- PLC controls Heating Prfiles

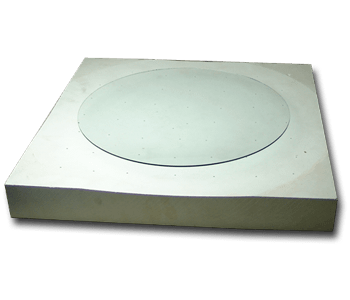

Glass Bending, Slumping & Fusing Moulds

- Resist up to 1000℃

- Extremely Low Expansion of Coefficient

- Extraordinary Low of Heat Conductivity

- Excellent Strength

- Anti-Corrosive & Anti-Bugs

- Surface Free of Chips for Glass Surface Scratch Proof

- Crack Free Despite Frequent Heating & Cooling

- Mould Sizes & Shapes Dimensional Stable

The Most Comprehensive Selected Top Class Chinese Glass Machines, Products and Services Resource

The Most Comprehensive Selected Top Class Chinese Glass Machines, Products and Services Resource

Glass Fabricating Machines | Glass Processing Machines | Glass Furnaces | Glass Ovens | Glass Manufacturing & Production Equipments | Glass Accessories | Glass Toolings | Glass Supplies | Glass Consumables | Glass & Mirror | Glass Engineering | Glass Contracting | Glass Consulting | Glass Services- Contact Us | Terms of Use Copyright © 1989 - 2020 Xinology Co., Ltd. All Rights Reserved.