Preheat

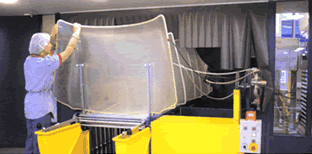

Pre-Heating & Vacuum Conveyor Oven (Glass Travels Vertically)

FEATURES

- PLC Conveyor Design Heating & Vacuum Oven for Mass Production

- Hot Air Convection Heating

- Glass Travels Vertically

- Consists of Oven Body, Conveyor, Vacuum System, Heating System & Control System

- Stable Chain Conveyor Carries Glass Consistently

- Vertical Rods Attached to Conveyor

- Frequency Converter Infinitely Regulate Glass Travel Speed

- Well Assembled Laminated Glass with PVB Films Loaded on Conveyor Separated by Vertical Rods

- Hoses of Silicon Rubber Rings Connected to Vacuum Pipes Inside Oven

- Vacuuming Evacuates Air Trapped Between Two Pieces of Glass by Means of Silicon Rings

- Air Fan Creates Powerful Hot Air Convection to Uniformly Preheat Glass & PVB Films

- Glass Edges Well Sealed with Pre-Melting & Pre-Bonding between Glass & PVB Film

- Well Thermal Insulation Materials of Oven Body Minimizes Heat Loss

- Automatic Heating Control

SPECIFICATIONS

| Models | LGVH-B-V-1015 | LGVH-B-V-1220 | LGVH-B-V-1525 |

| Max. Glass Size | 1000 x 1500 mm | 1200 x 2000 mm | 1500 x 2500 mm |

| Max. Temperature | 140℃ | 140℃ | 140℃ |

| Productivity | 300 pcs/8 hrs | 300 pcs/8 hrs | 300 pcs/8 hrs |

| Total Power | 60 KW | 70 KW | 90 KW |

| Outer Dimensions (LxWxH) | 10 x 2.3 x 3.1 m | 10 x 2.8 x 3.3 m | 10 x 3.3 x 3.4 m |