Preheat

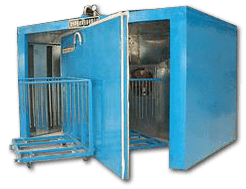

Pre-Heating & Vacuum Cabin Oven

FEATURES

- Batch Design Heating & Vacuum Oven

- Budget Investment for Medium Small Productivity

- Consists of Oven Body, Vacuum System, Heating System, Control System & Glass Trolley

- Well Assembled Laminated Glass with PVB Films Loaded on Rack

- Hoses of Silicon Rubber Rings Connected to Vacuum Pipes Inside Oven

- Air Fan Creates Powerful Hot Air Convection to Uniformly Preheat Glass & PVB Films

- Vacuuming Evacuates Air Trapped Between Two Pieces of Glass by Means of Silicon Rings

- Glass Edges Well Sealed with Pre-Melting & Pre-Bonding between Glass & PVB Film

- Well Thermal Insulation Materials of Oven Body Minimizes Heat Loss

- Automatic Heating Control

SPECIFICATIONS

| Models | LGVH-A-1520 | LGVH-A-2030 | LGVH-A-2536 | LGVH-A-3050 |

| Max. Glass Size | 1500 x 2000 mm | 2000 x 3000 mm | 2500 x 3600 mm | 3000 x 5000 mm |

| Max. Temperature | 140℃ | 140℃ | 140℃ | 140℃ |

| Quantity (Base on Largest Glass) | 40 Pcs/Batch | 40 Pcs/Batch | 40 Pcs/Batch | 40 Pcs/Batch |

| Productivity (Depends on Glass Qty) | 1.5 ~ 2.5 hrs | 1.5 ~ 2.5 hrs | 1.5 ~ 2.5 hrs | 1.5 ~ 2.5 hrs |

| Total Power | 50 KW | 68 KW | 80 KW | 100 KW |

| Outer Dimensions (LxWxH) | 2300x1800x2500 mm | 3300x2300x2500 mm | 3900x2800x2500 mm | 5300x3300x2500 mm |

OPTIONS

Self-Rotated Door

Door could be designed such that it is self rotated. Two glass trolleys are attached to two sides of door. While one glass trolley is being processed inside preheating and vacuum oven, glass trolley outside oven is being loaded or unloaded. The design helps handling of glass trolley especially when it is fully loaded with glass. Meanwhile, it reduces downtime of oven and thus, increases productivity.

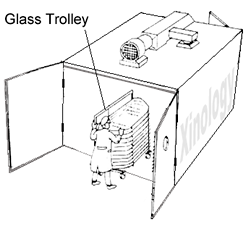

Glass Trolley

The cabin oven comes with only one glass trolley. Extra glass trolley is supplied on request. When one glass trolley is inside cabin oven for processing, another glass trolley is being loaded and assembled with rubber rings. After de-airing process is accomplished, glass trolley is brought out of cabin oven and glass is ready for unload. Empty glass trolley is then brought back to assembly room for next loading. Extra glass trolley increases productivity and reduces idle time.