Preheat

Introduction

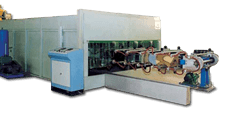

After windshield bending and PVB is assembled, air is trapped in between two pieces of glass. It is necessary to evacuate air under certain temperature until all air bubbles are removed and meanwhile, windshield edges are sealed with melting and bonding of PVB. This process is undergone in a heating oven with vacuum capability. This pre-heating and vacuum oven, sometimes also known as deairing oven, is available in two designs, cabin style and conveyor style. There are also two design for conveyor style, horizontal or vertical designs depend on how glass travels.

LGVH-A Glass Pre-Heating & Vacuum Cabin Oven Batch Production Design for Budget Investment with Medium Small Capacity