Assembly

Introduction

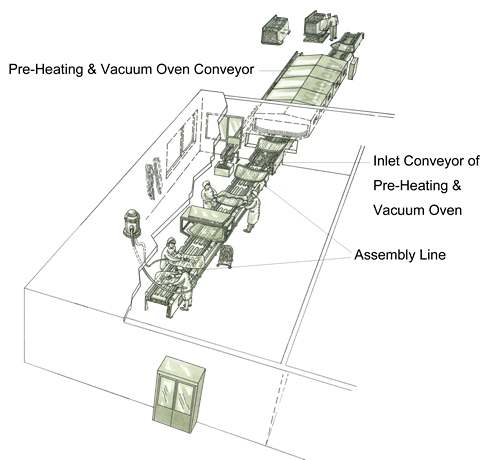

It is a conveyor line where following procedures are carried out,

- Power Removed

- Assemble PVB Interlayer in between Two Pieces of Glass

- Trimming of Excess PVB Film around Glass Edges

- Wrap Silicon Rubber Rings around Glass Rim

The assembly conveyor is usually installed in a climatic control room where temperature and humidity are controlled. The longer is conveyor length, the higher is the productivity. The assembly conveyor could be incorporated in line with subsequent pre-heating and vacuum conveyor oven. This design minimizes glass handling to the least labor force while for continuous mass production.