Features

Electrical & Control Systems

The electrical and control cabinet is located next to the machine. It includes,

- Air Conditioning System

- Main Switch with External Handle

- Power and Control Equipments

- PLC

- Push button: Power ON / OFF

- Lights: Power / Auto / Default

- Emergency button for shut down

- Safety acknowledgement

Commands and Signals

- Conveyor speed

- Water temperature

- Air temperature

- Flaps opening range

- Quantity of glass entering in and existing out (+ reset)

Parameters (Settings and Display)

- One push button for side air knives up

- One push button for side air knives down

- One push button for upper middle brush up / down (option)

- One push button for lower middle brush up / down (option)

- One push button for upper side brushes up / down (option)

- One push button for lower side brushes up / down (option)

- One push button with light for request access to washing machine

- One push button to terminate the request access to washing machine

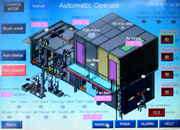

Control Panel

- All pages could be accessed through main manual

- Manual control of devices

- Automatic parameters (setting could be only when cycle is completed)

- The default display includes Auto/Manu, heating cycle start/stop, washing cycle start/stop.

- There is an error manual.

- All pages display date/time, manual title and is capable to access to any other pages.

HMI Touch Panel Human-Machine Operator Interface

Logic

- All controls and displays are achieved through the touch panel.

- All devices could be controlled individually while the error alarm and safety devices are still activated.

- Washing pump is started up (high pressure pump and valve in front of the high pressure pump are shut down, valve in front of sprinkle nozzles is switch on).

- High pressure washing

- Pumps of pre-washing and washing are started up (high pressure pump and valve in front of the high pressure pump are shut down, valve in front of sprinkle nozzles is switch on).

- Brushes are lifted up and lowered down to provide sufficient enough space to avoid get in contact with glass and run in low speed.

- The pressure belt (or wheels) of the conveyor is lifted up too.

- Washing cycle

-

- The pumps are protected against water with flow meter and water level controller.

- The interface signal is activated.

- When conveyor is stopped, the blower flap is closed.

- When there is no glass for 2 minutes, the blower flap is closed.

- When air filter is blocked, there is an alarm.

- When any of the devices is faulty, the machine is stopped. The fault is displayed.