Features

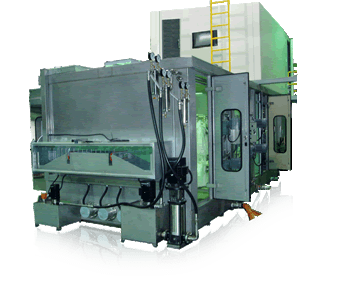

Drying Section

Stainless Steel Enclosure

The enclosure is completed in one piece in which the frame and all parts are made of stainless steel. There are two access doors with one on each side. There are glass window panels in the doors with safety switch and lock.

The inner side of the enclosure is insulated with acoustic proof material and punched boards. They are used to reduce noise pollution. The acoustic material is burnt-proof, fire-proof, water-proof and free of dust.

Conveying System

The curve glass is conveyed by two parallel belt conveyors driven by synchrony-wheels.

The contact between the belt and the glass is made of polyurethane.

The frame of the conveyors, conveying shafts and synchrony-wheels are made of stainless steel. The bearings and the bearing bottoms are also made of stainless.

Conveyor motor is put inside a stainless steel cover and is located outside of the enclosure to keep away from water.

Conveyor motor is controlled by a frequency inverter.

There are sensors in the inlet and outlet of the conveyors of the washing section. They are used to detect the glass when it enters in and exits out of the washing section.

Dripping Section

There is a 500 mm long dripping section in between the washing and the drying sections. It is used to allow the water remained on glass to flow away as much as possible before entering into the drying section.

Air Knives System

Air knives are made of stainless steel.

Lengthwise knives and centre knives are equipped with manual adjustable device. During installation, they are adjusted once for all.

The right knives are installed in spatial linkage. The angle of the knives is adjusted by means of motor in compliance with glass camber.

The structure of the left knives is same as the right knives.

Air knife system consists of 4 parts,

- Two right knives (up \ down)

- Two left knives (up \ down)

- Two centre knives (up \ down)

- Two lengthwise knives (up \ down)

The positions of side air knives are indicated in a dial. The adjustable construction is made of the stainless steel. All air knives are equipped with manual flap for the adjusting of air flux. The air knives are put in such a way that they are overlap to each other. This is to guarantee the complete glass surface is covered by air knives. There are also small air knife beneath each of the belt. They are used to dry off the belt.

Anti-Static System

This system is equipped with a set of anti-static bars

- Anti-static bars are installed in the air outlet. It consists of right anti-static bars (up / down), centre anti-static bars (up / down) and left anti-static bars (up / down).

- Anti-static bars are installed once for all and no further adjustment is required.

- The anti-static bars are powered fan and high voltage transformer.

Pressure Balance Compensation System

Drying section comes with a vacuum pressure compensation system

- The exhaust fan will be installed in the top of the air drying section for decompression.

- The air pressure is controlled through touch panel.