Features

Quench

Flat Tempering

Quenching Section Consists of High Pressure Plenums to Exert High Air Pressure & Volume on Top & Bottom Hot Glass Surfaces until it is Tempered. Quench is also used for Glass Cooling.

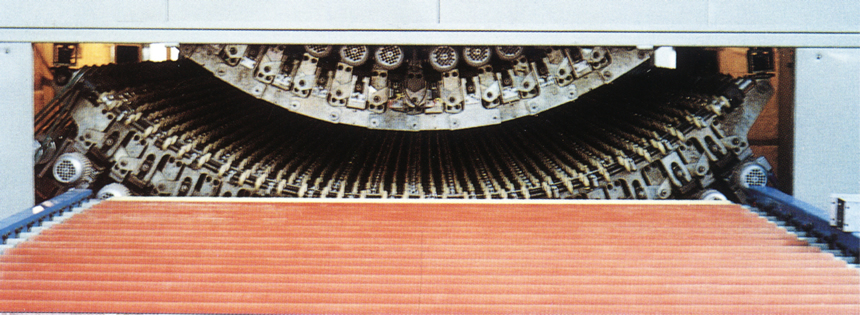

Transverse Bending & Tempering

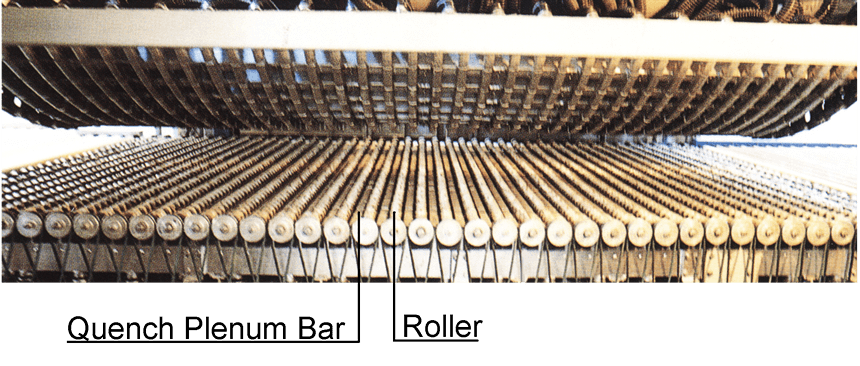

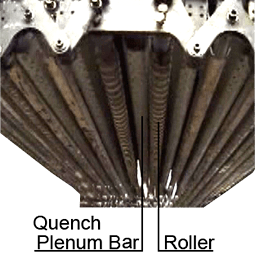

Glass Rollers & Quench Bars Curve into Identical Radius of Curvature Simutaneously

Quench Plenum Bar between Every Two Rollers in Transverse Rollers Bending System. Bending & Tempering done in this Same Section. Tempering carried out Right after Bending Minimizing Heat Loss