glass tempering

Glass Tempering Furnaces

- Glass Thermal Heating Furnace with Quenching for Glass Tempering

- Combo Hot Air Forced Convection Heating for Low-E Glass Tempering

- Optical Distortion Free Glass with Perfect Flatness

- High Mechanical & Flexible Strengths Glass

- Available with Flat & Bend Glass Tempering Furnaces

- Universal Adjustable Longitudinal & Transverse Glass Roller Bending Systems

- Mould Bending for Compound & Complex Glass Bent Temper Glass

- Ultra Thin & Tiny Glass Tempering Furnace

- Right Angles Bending & Tempering Furnace

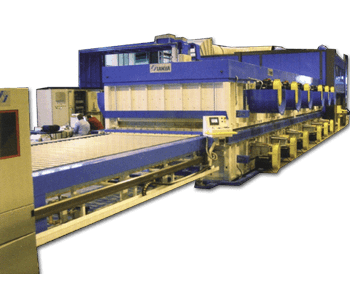

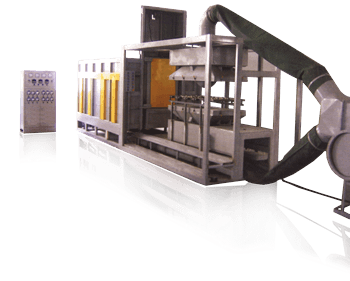

Combo Convection & Irradiation Glass Tempering Furnace

- Combo Air Convection & Irradiation Heating within Same Heating Chamber

- Convection Air Passes Through Heating Resistors

- Force Air Convection

- No Inducing of Cool Air Outside Heating Chamber

- Consume 27% Less Energy Than Irradiation Furnace

- Increase 30% More Production Throughput Than Irradiation Furnace

- 2 Times More Productivity Than Radiation Furnace for Low-E Glass

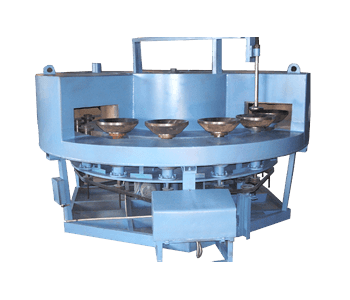

Glass Sinks Slumping & Tempering Furnaces

- Special Design to make Safety Temper Glass Sinks & Glass Basins

- Induce Glass Stress Obtaining High Impact Strength

- Produce Individual Glass Sinks without Glass Platform

- Produce also Glass Sinks with Connected Platform in One Full Glass Pane

- Computer Controlled Heating & Tempering Process

- Well Thermal Insulation of Heating Oven for Heat Preservation

Glass Lids & Cover Bending & Tempering Furnace

- Glass Covers Tempering done Right after Bending Minimizing Heat Loss

- Rotary Glass Oven Design Saves Space

- Free of Press Marks & Mould Marks

- Thermal Stable Glass Lids Resisting High Heat Cooking

- Lowest Energy Consumption

- Round, Oval, Square & Rectangular Glass Lids could be Made

- Glass Edging & Drilling Machines also Available

- Provide Complete Stainless Steel Strip Production Line

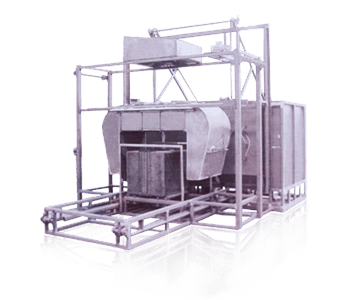

Glass Chemically Strengthening Equipment

- Produces Glass with Outstanding Strength

- Do Not Distort Flatness

- Free of Roller Marks

- Process Thin Glass Up To 0.5mm

- Unlimited Glass Shape & Min. Size

- Stainless Steel Ion Exchange Tank

- Chemical Process Done Automatically

- Upper Platform Allow Chemical Loading & Easy Maintenance

- Optional Produces Monolithic Fire Proof Glass

L & U Shapes Glass Tempering Furnace

- Non-roller hearth heating oven design free of roll marks

- Two steps process, glass bending & glass tempering

- Produce single angle glass bending (L shape) or double angles glass bending (U shape)

- Adjustable quenching plenum for different glass sizes tempering

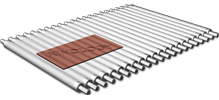

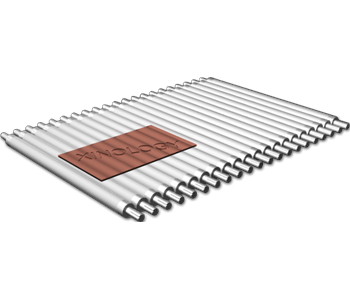

Fused Silica Rollers

- Fused Silica Rollers or Ceramic Rolls Specially Designed for Glass Conveying of Glass Tempering Furnaces

- Smoothest Roller Surface Leaves No Marks on Glass

- Perfect Straight & Concentric Rollers Account for Wave Free Tempered Glass

- Scratch Proof Roller Surface

- Very High Compressive Strength, Flexural Strength & Impact Strength at High Temperature

- Excellent Thermal Stability & Thermal Shock Resistance

- Available in Various End Cap & Shaft Designs Suitable for All World’s Glass Tempering Furnaces Manufacturer Brands

- Available in Versatile Diameters & Lengths

The Most Comprehensive Selected Top Class Chinese Glass Machines, Products and Services Resource

The Most Comprehensive Selected Top Class Chinese Glass Machines, Products and Services Resource

Glass Fabricating Machines | Glass Processing Machines | Glass Furnaces | Glass Ovens | Glass Manufacturing & Production Equipments | Glass Accessories | Glass Toolings | Glass Supplies | Glass Consumables | Glass & Mirror | Glass Engineering | Glass Contracting | Glass Consulting | Glass Services- Contact Us | Terms of Use Copyright © 1989 - 2020 Xinology Co., Ltd. All Rights Reserved.