Features & Specs

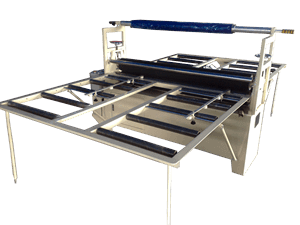

FASM-A Standard Films Applying & Sticking Machines

Introduction

Some glass, for example reflective coated glass, requires protective films adhering on glass surface. FASM-A series film adhering machines are used to apply film layers on glass surfaces. Machines are operated off line. Some glass is required to applied films on both surfaces. FASM-A is available with optional double side adhering capability by passing the machine in one time. Mirrors back are also adhered with protective films for safety purposes. The machines are also mirror back film applying and affixing machines.

Options

Double Sides Films Gluing

Some glass requires both surfaces applied with films. This option includes another film supports and film stretcher installed beneath conveyor rollers. Top and bottom surfaces of glass are affixed with films at the same time.

Film Protective Layer Winding

Some films are surface protected with a thin layer. When film is applied on glass, this protective layer is no more necessary and it is peel off. This winding system is used to peel off and wind up the film layer when film is being applied on glass.

Specifications

| Models | FASM-A-1300 | FASM-A-1600 |

| Max. Glass Width (mm) | 1300 | 1600 |

| Max. Glass Length (mm) | 2200 | 2700 |

| Min. Glass Width (mm) | 100 | |

| Min. Glass Length (mm) | 500 | |

| Glass Thickness (mm) | 3 ~ 25 | |

| Top Press Roll Rotation | Idle | |

| Bottom Press Roll Rotation | Motorized Driven | |

| Top Press Roll Vertical Movement | Hand Wheel Adjustment | |

| Top Press Roll Vertical Lifted Length (mm) | Max. 70 | |

| Bottom Roll Vertical Movement | Fix | |

| Press Roll Diameter (mm) | Φ 160 | |

| Press Roll Rubber Thickness (mm) | 15 | |

| Glass Speed (m/min.) | Max. 16 m/min. | |

| Inlet / Outlet Conveyors Rollers | Idle | |

| Conveyor Rollers Distance (mm) | 150 mm / 300 mm | |

| Working Height (mm) | 780 ± 20 mm | |

| Voltage | 380V / 3 Phase / 50Hz | |

| Power (KW) | 1.1 | 1.1 |

| Inlet Conveyor Length (mm) | 1500 | 1500 |

| Rubber Press Roll Section Length | 490 | |

| Outlet Conveyor Length (mm) | 1500 | 1500 |

| Outer Dimensions (LxWxH) (m) | 3.5 x 1.8 x 1.8 | 3.5 x 2.1 x 1.8 |