Features & Specs

- Introduction

- Structure

- Operation

- Options

- Specifications

Structure

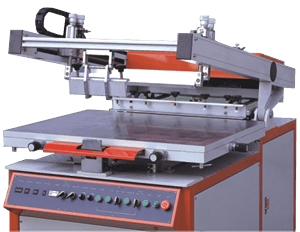

Printing Table

It is a flat bed structure with printing bed covered with Teflon or other smooth materials which is scratch proof to glass when it is being loaded, printed or unloaded. There are knobs at two sides of printing bed. When glass is loaded on printing bed, stencil is lower done and the knobs are used to adjust glass position so that it is in alignment with screen image.

Air Blower

There is air blower beneath printing bed. There are air holes on printing bed. Air blower creates air cushion on printing bed to float glass while it is traveling. When air blower reverses rotating, it creates vacuum, if necessary, to hold glass firmly in place during printing.

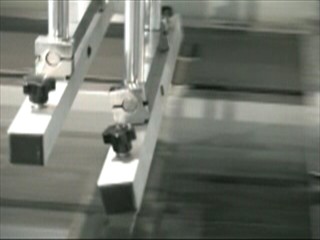

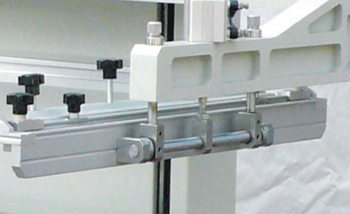

Bars

They are similar bars usually made of rubber. Squeegee bar is used to press ink onto glass surface through screen mesh. Flood bar recovers ink. Each bar can move up and down by pneumatic. Bar pressure acting on screen is adjustable. While one bar is working at down position, another bar is idle at up position. Inclined angles of bars to stencil are adjustable. There are adjustable handles with gauges to control up and down motion of both bars. Both bars are tightened by special locking system which allows easy loosing and clamping.

Bars Movement

The two bars run transversely above printing table. They are motorized driven through gear reductor with timing belt and high precision linear rack. Squeegee bar moves horizontally to bring and press ink onto glass surface through screen mesh. Flood bar recovers ink back to where it begins by moving back to its original position. Both bars move together. Moving speed is infinitely adjustable according to requirements. Adequate bar travel speed results in high printing quality while long life time of screen. Moving system is consistent to guarantee remarkable printing performance. Stroke length is adjustable according to image printing length.

Stencil Up & Down

Cantilever Structure - Distance between stencil and glass is adjustable. Vertical movement is achieved by high precision photocell and limit switch. There is a safety system preventing screen from over travel when it reaches at lowest or highest position.

Tilting Structure - It is design for small printing areas. Screen frame holding system is incorporated to this tilting system activated by pneumatic cylinders.

Peel Off

It is used to push and tilt slightly the stencil while squeegee bar is moving. Titling action is synchronized with squeegee bar travel speed with the help of motorized pneumatic cylinder. Better ink printing quality is obtained when stencil is slightly detach and peel off from glass surface while printing. An auxiliary quick return device is equipped. It guarantees ink recover is performed only after screen frame is back to perfect horizontal level when peel off is done. Peel off tilting height is also adjustable.

Control System

It consists of electrical and electronic components to control all movements and sequence of operations. Bars movement and screen frame up and down movement are managed by carefully selected frequency converter.

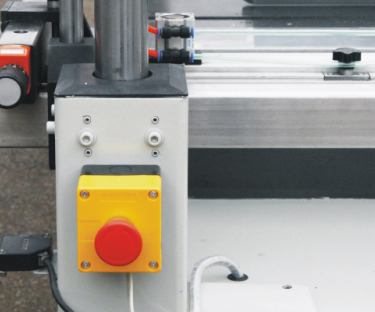

Safety Precautions

Machine will stop operation whenever emergency button is pushed.