Features & Specs

- Introduction

- Structure

- Operation

- Options

- Specifications

Structure

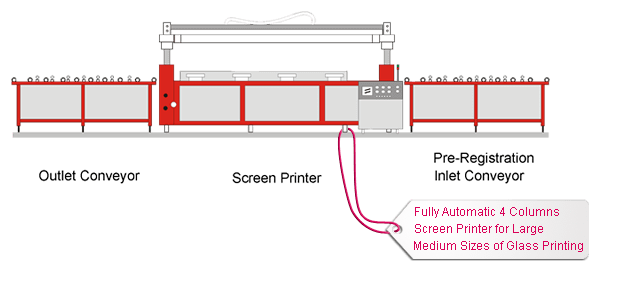

General

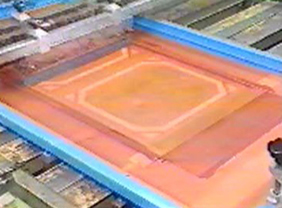

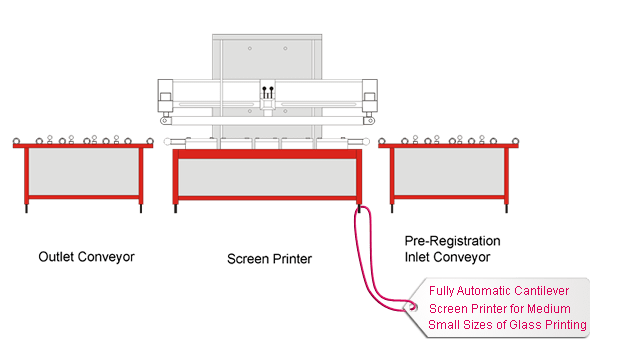

It is Composed of Pre-Registration Inlet Conveyor, Screen Printing Machine, Outlet Conveyor & Control System

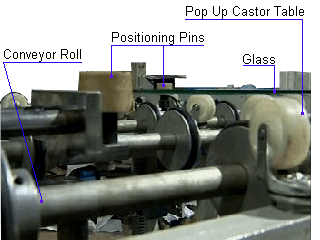

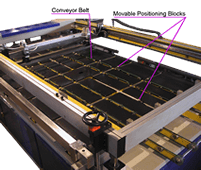

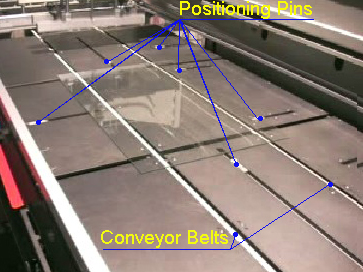

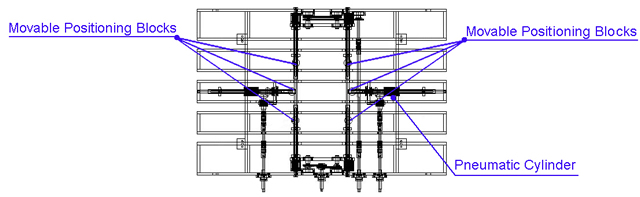

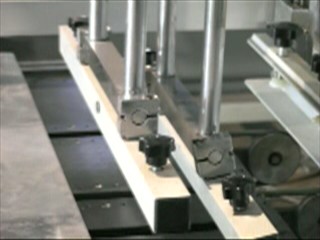

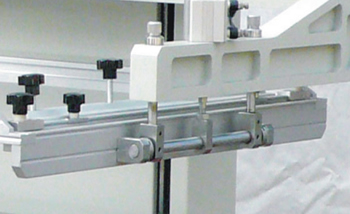

Pre-Registration

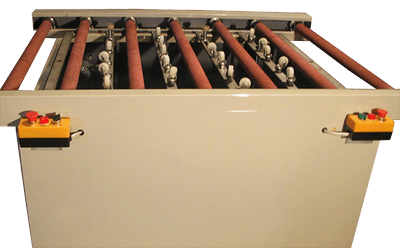

It is composed of two metal structures, one is convey rollers and another is a pop up castor table with registration system equipped with positioning blocks. Glass is loaded on the conveyor with castor table below rollers. Castor table pops up and the glass is pushed against positioning blocks until it is in correct pre-registration position. This mechanism ensures glass traveling into screen printer within final registration range. Roller begins to bring glass at synchronize speed into subsequent glass screen printing machine.

Outlet Conveyor

It is metal structure with conveying rollers. Glass exits from screen printer onto this outlet table at synchronize speed with printer's belt conveyor.

Control System

It consists of PLC and electrical and electronic components to control all movements and sequence of operations. All controls are access through a human machine interface touch panel. Bars movement, screen frame up and down movement and conveying speed are managed by carefully selected frequency converter.