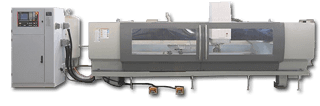

Structure

General

- Open Top Design with Front Sliding Doors Convenient for Glass Loading & Unloading

- Protective Guard Shed Around Machine

- Structural Welded Steel Movable Bridge

- Extremely Rigid Structure

- Y-axis Driven Structure Attached to Bridge

- X-axis, Y-axis & Z-axis Driven by High Precision Ball Screw Sliding on Sliding Slide Way

- C-axis for Rotation

- Y-axis & Y1-axis are Synchronous & Equipped with Servo Motors Driving by Slide Way & Ball Screw

- Easily Achieve High Acceleration & High Processing Speed Resulting Highest Production Throughput

- Maintains Highest Precision & Quality due to Lowest Mechanical Abrasion

- Central Lubricated Movable Parts

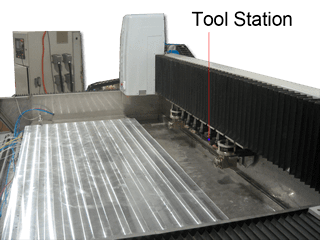

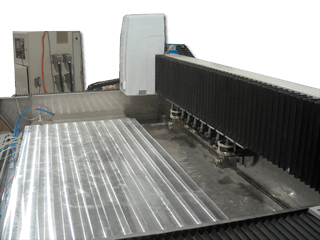

Working Table

The table is made of harden aluminium alloy with enclosure preventing water from splashing. Operators can access to working table either front or rear side. Suction cups and locators are mounted on table top. They can be repositioned on table top according to glass shapes and sizes. Glass is loaded on suction cups against locators for positioning. Compress air pipes and vacuum pipes are connected to corresponding positions.

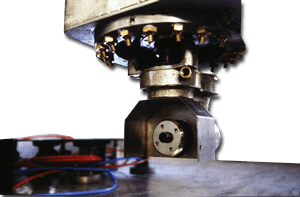

Electro-Spindle

It is core heart of glass working centre. High and constant torque output greatly improves processing speed and enables applications of versatile tooling in larger diameters. High precision structure and top quality parts and components. Thanks to sophisticated design, size and weight of spindle are minimized. This is to reduce inertia when spindle is rotating in high speed and thus, improve acceleration and deceleration of spindle. Water coolant runs in spindle core maximizing cooling efficiency. This is particularly helpful during drilling, milling and routing.

Working Head

Tools and electro-spindle are installed and mounted on this working head. C-axis of working head rotates 360o freely. Specially design jigs and fixtures may be required for certain applications such as glass bevelling, disc cutting (option) and engraving (option). Jigs and fixtures are used to support and hold adequate tools.

Water Cooling System

It is used to cool down tools and work pieces. It comes with water pump and stainless steel water tank for recycling.

CNC System

Carefully selected professional numerical control system integrated with user friendly PC Windows operating interface. The system is equipped with CD-Rom and USB drivers, colour monitor, keyboard and mouse. The system comes with necessary port for accessing to internet. Remote diagnostic is available for real time monitoring. Programming edit is allowed when machine is in operation.

- Spindle Loading Displayed in Monitor

- Current Work & Total Working Time Displayed in Monitor

- Graphics Showing Tools Processing Routes & Profiles

- Storage Up To 254 Tools

- Support Milling / Edging / Polishing / Drilling / Drawing & Writing / Engraving / Groove Polishing / Bevelling / Cutting

- Support Both Automatic & Manual Compensation for Polishing

- Self-Defined Tool Measurement Supports “No Measurement”, “Measurement against Tool Changing” & “Measurement at One time”

Cimatron Software

- Used for Control System

- Support DXF Files

- Shape Drawings Designed by CAD or Input Files from CAD System

- Software Self Checks the Feasibility of Processing Automatically

- Images & Files Stored Management

- Optimization Software for Tool Route Minimizing Processing Time

- Route Simulation of Drawing Processing