Operation

- Wash and dry glass thoroughly.

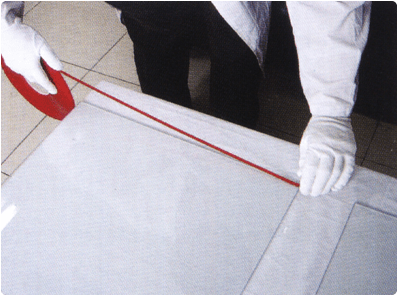

- Apply double-sided adhesive tape to the perimeter of one piece of glass sheet. Then assemble another piece of glass on this glass. Leave an opening for subsequent resin dispensing. The tape acts as a dam or barrier to prevent liquid resin from leaking during dispensing. Tape's thickness shall be the thickness for liquid resin interlayer.

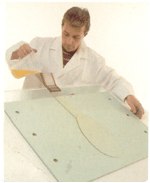

- Glass is put on a slightly inclined table. Insert a flat mouth funnel into the opening. Pour liquid resin into the funnel. Resin fills the space between the two panes of glass. Resin spreads all over glass cavity until every corner is filled up.

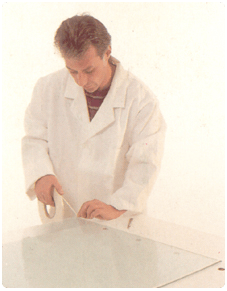

- Remove the funnel. Seal the opening with tapes.

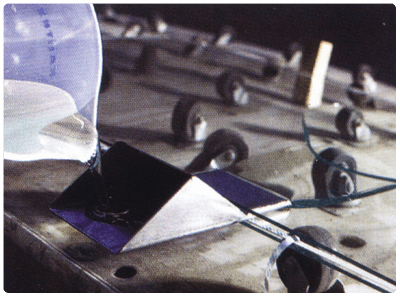

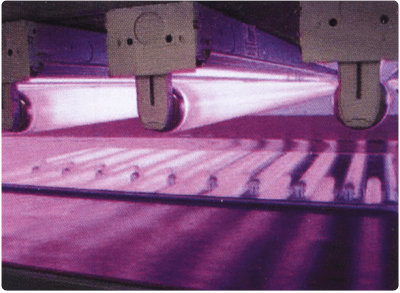

- Place glass under UV. UV source could be outdoor natural sunlight exposure or indoor UV lamps. After certain time UV exposure, laminated glass is done.