Glass Vacuum & Laminating Oven (Autoclave Free)

- Overview

- Features & Specs

- Video

Overview

- EVA Interlayer In Between Two Pieces of Glass

- EVA Interlayer & Decorative Design Film In Between Two Pieces of Glass

- EVA Interlayer & Functional Film In Between Two Pieces of Glass

- EVA Interlayer & Back Plastic Film Laminated with One Piece of Glass

- EVA Interlayer, Decorative Design Film & Back Plastic Film with One Piece of Glass

- EVA Interlayer with Multi-Layers of Glass & Polycarbonate

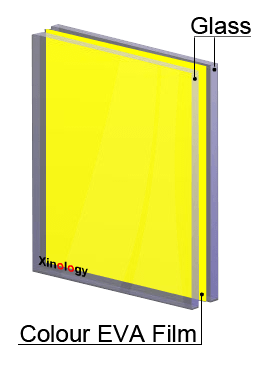

EVA Interlayer In Between Two Pieces of Glass

This is the basic configuration of EVA laminated glass. The EVA film could be clear, white, colour transparent colour translucent or colour opaque, etc. It could be single layer or multi-layers of EVA. Glass could be ordinary clear float, tint, solar control or figure roll, etc.

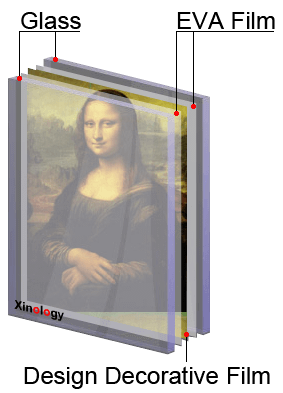

EVA Interlayer & Decorative Design Film In Between Two Pieces of Glass

To obtain aesthetic visual effect, a piece of decorative design film could be sandwiched in between two pieces of glass encapsulated by top and bottom layers of EVA films. The decorative film could be fabric, PET, non-woven, metal net, fiberglass and paper, etc.

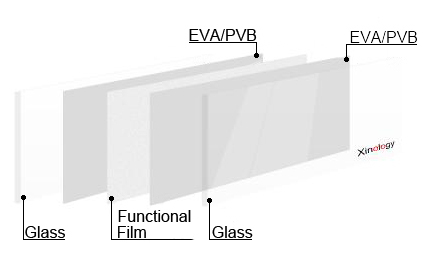

EVA Interlayer & Functional Film In Between Two Pieces of Glass

One of the most popular functional films is PDLC which turns transparent when voltage is applied and becomes opaque instantaneously when voltage is disconnected. Like decorative film, PDLC film is sandwiched in between two pieces of glass encapsulated by top and bottom layers of EVA film. This EVA film is specially formulated so that it is compatible to PDLC film.

EVA Interlayer & Back Plastic Film Laminated with One Piece of Glass

If both shatterproof and weight are major concerns, EVA film could be, with a protected Back Plastic Film, directly laminated on a single piece of glass. The Back Plastic Film should come with hard coating for scratch and abrasive proof. No top glass is required. When high impact is an additional concern, temper glass is employed.

When there are two pieces of glass with one or both tempered, air bubbles or de-laminations could be easily found. This is because temper glass is generally wavy and gaps between the glass may not be adequately fully filled up with melted EVA. This is now overcome by laminating only one piece of temper glass with EVA film covered by protective Back Plastic Film, usually PVC. This design is light, tough and shatterproof while at low cost.

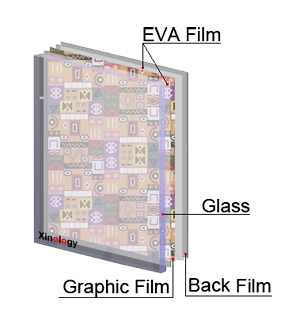

EVA Interlayer, Decorative Design Film & Back Plastic Film with One Piece of Glass

With only one piece of glass, probably temper, this configuration on one hand provides high impact while bears aesthetic visual effect when laminated with decorative design film. It is also shatterproof when glass is accidentally broken.

EVA Interlayer with Multi-Layers of Glass & Polycarbonate

Layers of glass, polycarbonate and EVA could be laminated together. When security and safety are major concern, this type of glass configuration would help. While laminating with decorative design film and/or functional films such as PDLC, it becomes a design or functional high security glass.