Features & Specs

- Introduction

- Description

- Options

- Layout

- Specifications

Description

General

Laminated glass is final bond inside autoclave under certain pressure and temperature. This pressurized vessel is composed of several components.

- Autoclave Body

- Autoclave Door

- Infra Red Heating System

- Cooling System

- Pressurize System with Air Tank

- Safety System

- Control System

- Handling System

Body

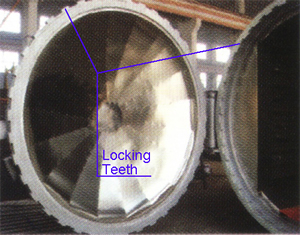

Materials, fabricating process and welding of the body strictly comply with provisions and National standards as well. All welding and those areas to be resistant under high pressure are 100% non-destructive tested. Body is design to resist high pressure persistently under long period of time. Fan blower for heat circulation is mounted at the end of autoclave body. There are special double seals to ensure no air leaking. There are air channels inside autoclave. Hot air is re-circulated via the channels. There are floor rail tracks for glass rack moving in and out of autoclave. There are "teeth" around inner circumference of autoclave entrance. They are used to interlock with door.

Door

Doors of large models of autoclave are electrically motorized opened and closed automatically. Smaller models are opened and closed manually. Sophisticated door locking system and special gasket design guarantee door is tightly sealed under working pressure. With interlocking design, door remains locked and is not allowed to open unless autoclave pressure drops to atmospheric pressure. There are "teeth" around door circumference. Motor drives to turn door, "teeth" lock with "teeth' of autoclave. This locking design resists high pressure.

Heating System

LG-AC-B series is an autoclave using revolutionary infra red heating system. Instead of conventional heating resistors, IR heaters are used. The heaters are installed in two sides and bottom of autoclave. These IR heaters are specially design such that it emits frequency which is absorbed by PVB interlayer film. This process highly reduces power consumption versus traditional heating resistors which heat up air, then glass and finally PVB film by means of heat conduction. Heating time is also reduced due to high efficient IR heaters. Temperature could be regulated. There are thermocouples inside autoclave. They are used to measure monitor temperatures. Temperature is monitored in real time and is automatically compensated to maintain always at constant temperature. Infrared heating system does not require hot air circulation. Therefore, no hot air fan motor nor driven motor is required.

Water Cooling System

After heating is accomplished, autoclave is required to cool down. Water is medium to help cooling down the hot air inside autoclave. Water is re-circulated by means of a cistern (to be provided by buyer).

Pressurize System with Air Tank

Air tank is a pressure vessel which is used to store air generated by optional air compressor. When air tank is filled with pressurized air, pressure valve of autoclave is released. Pressurized air rushes into autoclave to create necessary pressure for glass laminating. Pressure is monitored in real time and is automatically compensated

to keep always at constant pressure.

Air Releasing System

When heating and pressurized processes are accomplished, some valves located on top of autoclave are activated. Pressurized hot air inside autoclave is released.

Safety System

There are safety precautions with over heating and over pressure protections. When temperature is over set value, it alarms and temperature drops automatically. When pressure is over set value, it alarms and over pressure valve is activated automatically to release air. Meanwhile, temperature drops automatically.

Handling System

Transition Platform

It is a movable metal structure situated inside autoclave pit (to be provided by buyer) and is located in front of autoclave. It is a connection between workshop floor and autoclave floor. It allows glass rack moving in and out of autoclave. There are rail tacks on pit floor. Transition platform runs on rail tracks with wheels. It is moved aside while autoclave door is being opened or closing. There are rail tracks on the metal platform. When platform is moved right in front of autoclave while door is opened, rail tracks are aligned such that they connect workshop rail tracks and autoclave rails tracks together.

Glass Trolley

It is a metal structure with heat resistance wheel bearings. Large self lubricated bearings make moving easy. It carries glass in and out of autoclave by means of rail tracks.

Rotating Platform

It is a round metal structure with cross rail tracks. It turns glass rack in 90 degrees when necessary. Foundation of this platform is provided by buyer.