Features

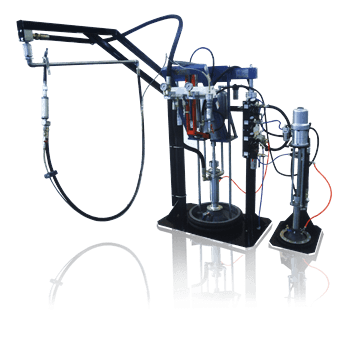

IG-TP-A

Introduction

IG-TP seroes two parts sealant extruding machine is designed to apply secondary sealant around insulated glass edges for final seal. It is applicable for most available sealants such as polysulfide, silicon and polyurethane, etc. These sealants are composed of two parts, Part A and Part B. Mixing ratio of Parts A and B is adjustable according to different materials and different manufacturers.

The process includes melting, pressurizing, scaling, mixing and extruding.

Structure

Scaling System

Flow rate of each component is then carefully scaled by this system.

Pressure System

IG-TP-A employs pure pneumatic system for pressurization. Extrusion of both Parts A and Parts B are powered by pneumatic system. No electricity power is required. Pure pneumatic system allows fast flow rate and large flow amount. This results in higher productivity. Critical parts and components such as main motor, auxiliary motor and safety valve are by Graco, USA, which is the world’s best known manufacturer for such system.

Mixing System

Scaled components are transported to mixing system where they are thoroughly mixed together until consistent. The mixer is equipped with a one way valve. It is used to prevent the two components from flowing back to each other during mixing. The flow back may block the channels. Different sealant has different mixing ratios. Mixing ratio is adjusted until adequate ratio is obtained for particular sealant. This adjustment is done once for all.

Sealant Gun & Nozzle

Well mixed component are then transported through hose and is finally extruded through sophisticated sealant gun and nozzle. Sealant gun is by Graco, USA.