Options

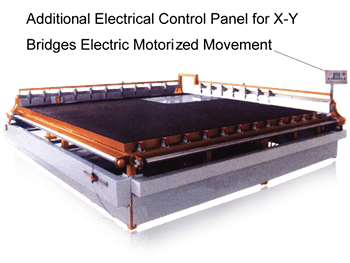

Electric Motorized Driven Bridges

Electric motors could be added to drive both of X and Y cutting bridges. By pressing button, bridges would travel transversely and longitudinally forward and then backward to perform X-Y cuttings automatically. PLC is included. Large models come with electric motorized cutting bridges as standard. Manual bridges movement is unavailable. See Specifications for details.

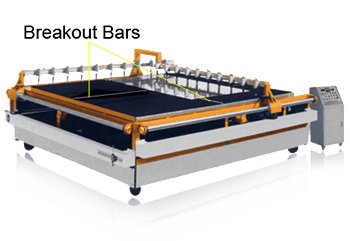

Breakout Bars

X and Y breakout bars could be incorporated into cutting tables. When glass is scored, glass breakout is carried out right away. Glass that can be scored is as thin as 3mm. This is because thinner glass may break when cutting wheel scores right above breakout bars. Optional breakout bars may be inapplicable for some small models. See Specifications for details.

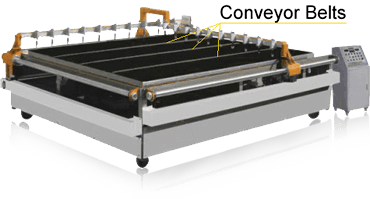

Conveyor Belts

Conveyor belts could be incorporated into cutting tables. The belts pop up above table level when conveying glass. They are lower down below table surface during glass scoring. This option is particular useful when cutting table is incorporated with loading table and/or breakout table especially for large or jumbo sizes of glass. The belts conveyer could bring glass into cutting table and also bring out of cutting table onto breakout table. Glass that can be scored is as thin as 3mm. This is because thinner glass may break when cutting wheel scores right above conveyor belts.

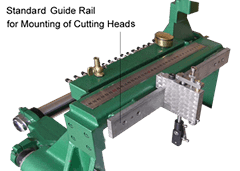

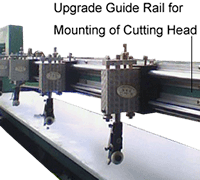

Upgrade Guide Rail for Cutting Head Mounting

This bearing design guide rail is an upgrade high precision structure. It allows faster and easier cutting heads spaces adjustments when changing scoring width. Dismantling and mounting of cutting heads are much easier and faster.

Ultra Thin Glass Cutting

Standard cutting table bed is covered with felt which allows cutting as thin as 2mm glass. When cutting of ultra thin glass such as 0.5mm is required, metal table bed is used. The metal plate surface is fine grind and polished so that it is perfectly flat. When cutting wheel, with downward force, runs and scores on ultra thin glass, perfect flatness of table bed prevents cutting wheel from breaking glass. Metal surface is covered with smooth non-scratch material such as Teflon.

10mm Cut Glass Size

Usual smallest glass size cut by the machines is 25 x 25mm. The machine can be upgraded to cut as small as 10 x 10mm.

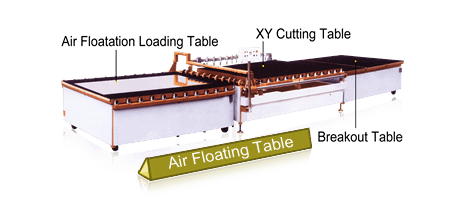

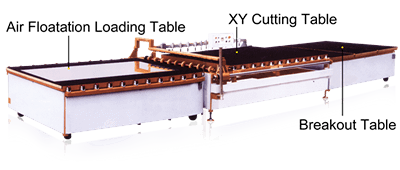

Glass Breakout Tables

A breakout table, with air cushion, could be incorporated right next to the cutting table. After cutting, the glass is transported to this breakout table by means of air floatation. There are several advantages of using breakout table,

- If glass is breakout in the cutting table, there are a lot of tiny glass flake left on the cutting table. The glass flake may cause scratches on subsequent glass.

- The flake may also affect the perfect flatness of the cutting table bed. When subsequent glass is loaded, the glass partially lays on the table bed and partially lays on the flake. This may affect the cutting performance.

- If breakout is done on cutting machine, the cutting machine is occupied and no cutting could be performed during breakout. This idle period would greatly reduce the production efficiency of the cutting machine.