Features

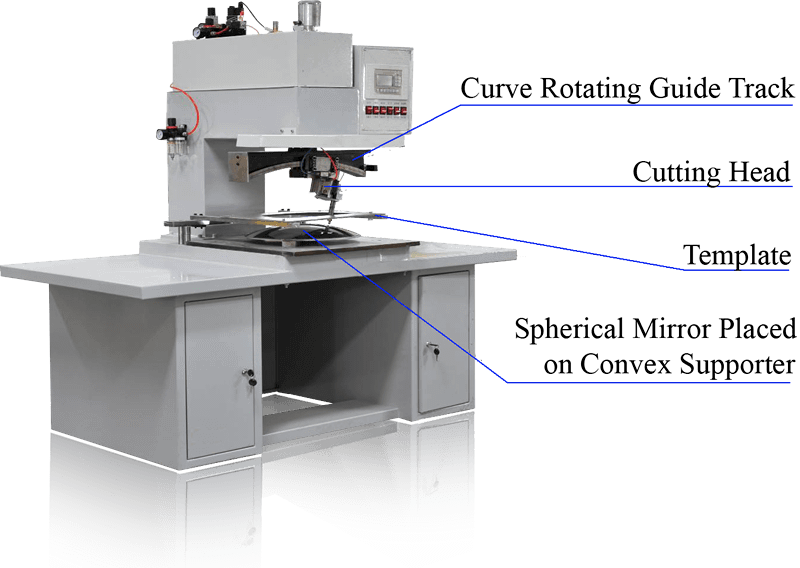

Spherical Glass & Mirror Cutting Machine with Templates

FEATURES

- Design for Spherical Glass & Mirror Cutting

- Budget Cutting Machine for Automobile Mirror Producers

- Cutting after Glass Bending

- Precision Curve Rotating Guide Track Made According to Spherical Mirror’s Radius of Curvature

- Sophisticated Cutting Head Slides on Curve Rotating Guide Track Until Requested Cutting Diameter is Achieved.

- Cutting Head Downward Pressure Regulated Automatically

- Cutting Head Lowers Down Slowly Towards Until Getting Contact Glass with Pressure Buffer

- Cutting Pressure Automatically Increased As Soon As Cutting Head Begins to Score

- Curve Rotating Guide Track Self-Rotates Performing Cutting

- Cut Various Radius of Curvature with Various Curve Rotating Guide Tracks

- Machine Delivered with One Curve Rotating Guide Track & One Corresponding Convex Supporter with Radius of Curvature Made According to Buyer’s Request

- Additional Curve Rotating Guide Tracks Provided with Extra Costs

- Additional Convex Supporters Provided by Buyer

- All Ring Mould Template Fixtures Are Provided by Buyer

- Round Cut Free of Template

- Optional Flat Glass Cutting Available on Request

SPECIFICATIONS

| Models | CUT-SC-TP-450 | CUT-SC-TP-700 |

| Table Bed Size | 500 x 500 mm | 700 x 700 mm |

| Max. Loaded Glass Size | 500 x 500 mm | 700 x 700 mm |

| Max. Cutting Diameter / Diagonal | 450 mm | 650 mm |

| Radius of Curvature | R150 ~ R2080 mm | R150 ~ R2080 mm |

| Glass Thickness | 1.0 ~ 4.0 mm | 1.0 ~ 4.0 mm |

| Cutting Tolerance | ± 0.1 mm | ± 0.1 mm |

| Cutting Speed (depend on perimeter length & shape) | 2 ~ 6 sec/pc | 2 ~ 6 sec/pc |

| Compress Air | ≤ 0.5 MPa | ≤ 0.5 MPA |

| Power | 0.25 KW | 0.25 KW |

| Voltage | 220V / Single Phase / 50Hz | 220V / Single Phase / 50Hz |

| Weight | 400 kg | 500 kg |

| Outer Dimensions (L x W x H) | 1500 x 750 x 1700 mm | 1500 x 1000 x 1700 mm |

OPTION

Curve Rotating Guide Track

One of the most critical parts of the spherical mirror cutting machine is the curve rotating guide track. Cutting head is mounted and moved along the guide track until requested cutting radius is reached. Cutting head is then locked onto guide track. When guide track self-rotates, cutting head starts to cut on glass. Radius of curvature of curve guide track is made and conforms to radius of curvature of spherical mirror to be cut. One radius of curvature of guide track can handle certain range of radius of curvature of spherical glass. Actual range that can be handled depend on various factors such as size of spherical mirror to be cut and diameter or diagonal to be cut. If necessary, an independent curve rotating guide track may be required for certain radius of curvature of spherical mirror. We do not guarantee the range of radius of curvature of spherical glass or mirror that recommended can be cut from certain curve rotating guide track.

If spherical glass to be cut is too large in size, the curve guide track may not be able to cut at glass edge area. It depends on actual cutting situation. We do not guarantee the curve rotating guide track can perform cutting properly on any size of spherical glass with corresponding radius of curvature.

The machine is delivered with one free guide track and corresponding base convex supporter with radius of curvature provided by buyer. Additional guide tracks are supplied at extra cost. Additional base convex supporters are provided by buyer. Unlike curve guide track, It is recommended to use one base convex supporter with radius of curvature conforming to spherical mirror to be cut. There is gap between glass and supporter if their radius of curvatures do not match to each other. When cutting wheel runs over glass, glass may be broken.