Overview

Glass Heat Soak Test

Introduction

Glass Trends To Be Self Destructed May Break During Heat Soaking

Heat soak test is to heat glass up and to maintain it at a specific temperature for a specific period of time thereby to impart a thermal history to the glass. Glass trends to be self destruction may break during heat soaking. It is reported that the longer the heat soak time, the more likely glass would break if it trends to self destruction. In other words, risk of self destruction may be reduced when heat soak time is extended. Heat soak test could not 100% remove all glass which may likely self destruction. It could only minimize the chances of self destruction.

Heat soak heating temperature is usually in the range of 100°C to 380°C. If heating temperature is lower than 100°C, the transition of nickel sulfide from α-NiS to β-NiS proceeds with considerable difficulty, and it is impossible to break a tempered glass sheet containing nickel sulfide during heat soak test. Temperatures in excess of 380°C do not cause the transition of the nickel sulfide from α-NiS to β-NiS.

Heat soak test could be carried out before or after glass tempering process. Due to chances of tempering failure, heat soak test is usually performed after tempering at practical industrial glass processing.

Principle

Heat Soak Test Is An "Accelerating" Process To Express The Imparting Of A Thermal History To A Glass Sheet By Maintaining It At The Temperature Specified And For The Time Specified

The "accelerating" after the tempering treatment of glass sheet is termed "post-accelerating" and the "accelerating" prior to the tempering treatment, "pre-accelerating".

During "accelerating", cracks around the foreign matter in a glass sheet are grown artificially, and the transition of the nickel sulfide from α-NiS to β-NiS is promoted artificially. By so doing, the glass sheet which will be spontaneously broken is broken at an early stage by the tensile stress which has been generated in an interlayer of the glass sheet by the tempering treatment.

Products still not broken after accelerating in the case of the process including post-accelerating or after the subsequent tempering treatment in the case of the process including pre-accelerating may further be rapidly heated at a temperature of 300°C to 950°C for 10 to 300 seconds so as to more strictly break and remove those tempered glass sheets which are likely to break spontaneously in the course of use. However, tempered glass made by the process of the tempering treatment and the accelerating will not be spontaneously broken during use in a normal condition even if it has not been subjected to this rapid heat-treatment.

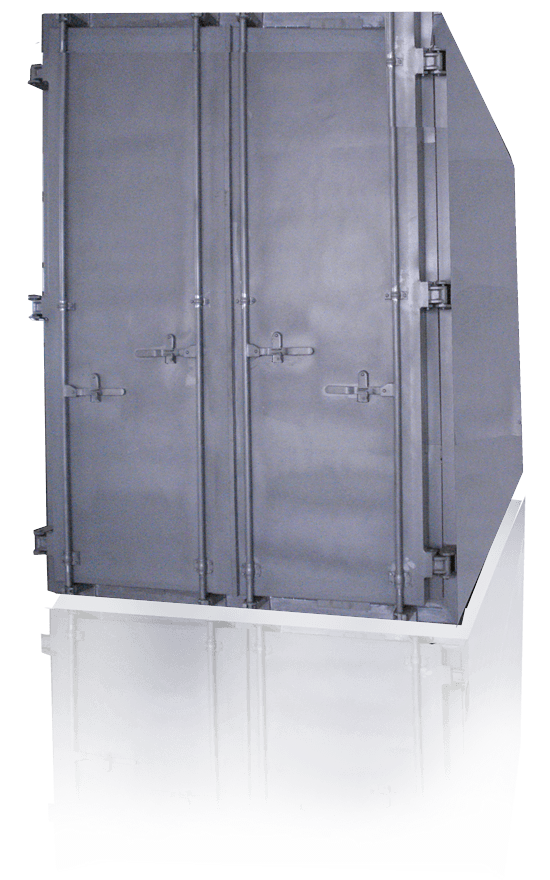

Heat Soak Oven

Xinology HSO Series Heat Soak Ovens Are Chamber Liked Heating Oven Where Glass To Be Tested Are Put Inside