Features

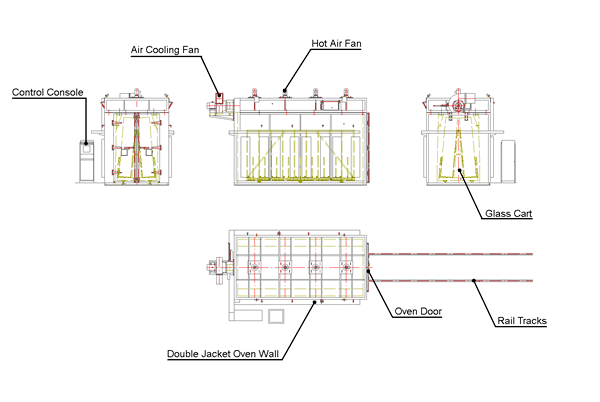

Oven Body

It is a chamber like structure painted with high temperature proof varnish. Interior wall is made of stainless steel plate. Layers of fine alumina silicate insulation materials are fully filled in double jacket wall for heat proofing. Door is opened outward. Rail track lies on oven floor.

Heating System

Heating resistors are used to heat up air. They are put inside stainless steel tubes which are hidden in oven double jacket wall. When air is re-circulated inside oven, air passes through resistors is then heated up. This hot air convection system thus heats up glass.

Hot Air Circulation System

Hot air fans are installed at oven top. They are heat proof and durable. It blows air through heating resistors. Air gains enough energy to heat up glass. It is a force convection design and air is totally circulated inside oven. This saves energy. Due to powerful air fan with sophisticated air channels design, glass inside oven is heated evenly in a fastest way.

Air Cooling System

It is a force cooling design to cool down glass rapidly. Powerful air fan greatly reduces production batch cycle time.

Glass Cart

Glass cart with high temperature resistance wheels is used to carry glass in and out of oven. It lies on rail tracks (to be provided by buyer) outside the oven. When oven door open, it is moved inside oven along rail track extending from ground floor to oven floor.

Control System

- Computer system with colorful monitor

- All operations and parameter are set and access through the computer

- Temperature profiles easily set, edited and stored in memory

- Programmable processing profile

- Production details and actual temperature profiles of each batch are recorded and could be printed out

- Intelligent PID temperature control

- Heating controlled by solid state relay

- Temperatures are measured by thermocouples

- Each measuring point is digitally displayed

- Over temperature alarm protection

- Power is 75% of rating

- Output terminal is composed of two ways SCR silicon control rectifiers

- Insulation voltage of input and output is 2500V

- Powerful data management

- Large storage capacity

- Multi-channels data acquisition

- Multi-channels output control

- RS232, RS485 and USB ports for connection with peripheral equipments