Overview

Introduction

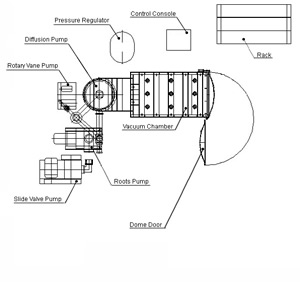

There are several ways to turn glass into mirror. Mirrors are obtained when reflective metals deposit on glass. Aluminum, chromium and nickel mirrors are three of the most popular mirrors around us everyday. Unlike silvering process, Al, Cr and Ni mirrors are made by thermal evaporation of metals under vacuum. Xinology EVC series aluminum, chromium and nickel mirrors production equipment is also known as thermally vacuum evaporation coating system. It is a thin film vacuum metallization deposition system with vacuum chamber, thermal evaporation system and vacuum system.

- Besides aluminum, chromium and nickel, some other metal coating mirrors could also be obtained from evaporation vacuum coating system, such as magnesium and gold, etc.

- Other than glass, EVC evaporation vacuum system could also apply metallic coatings on other substrate materials such as plastics and metals, etc.

Aluminium, chromium and nickel mirrors are substitutions of silver plated mirrors when are applied where silvering process is costly or simply impossible. Productions of aluminium, chromium and nickel mirrors are also environmental friendly.