Overview

Stencils Preparation

General

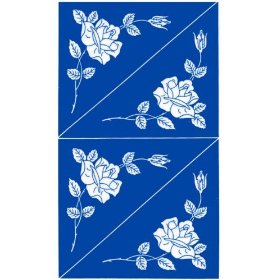

Sandblasting could be applied on complete glass surface or part of it. When an image or a pattern is required, stencils are usually required prior to sandblasting. Stencil is a thin layer of abrasive proof material covering those glass surface areas which require no blasting.

Steps

- Cover glass area not to be etched and expose the area to be etched by applying abrasive proof vinyl adhesive masking to glass

- Makes sure no air bubbles trapped between mask and glass

- Vinyl adhesive should be of the removable variety

- Lay the glass on top of the design to be etched

- Spell out words backwards because finished product usually looks best from the other side

- If it is a white adhesive paper, trace the design on with carbon paper or spray adhesive the back of design and stick it to contact paper and cut through both the design paper and the vinyl

- Shelf paper is generally 2 mils thick which is barely thick enough to sandblast safely without blasting through

- Double layer the 2 mil paper if thicker paper is necessary

- Cut around all the edges with an exact-o knife

- A vinyl plotter cutter is helpful to cut patterns in a faster and easier way

- Peel the area to be etched

- Cover the back of the glass if necessary

- Ready to sandblast