Overview

Abrasive Recycling

General

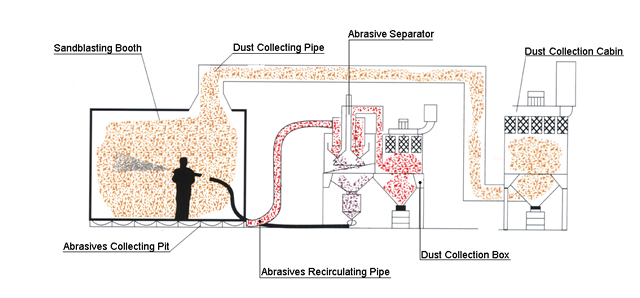

After blasting, some abrasives remain sharp in edge and large in sizes. They are still usable. However, these usable abrasives are mixed together with dusts generated during blasting. It is worthy to recycle usable abrasives for cost saving. Meanwhile, abrasives air blasting is a dusty process. Annoy dusts are required to be collected for disposal avoiding pollution. Recycling is an integrated process which

- separates usable abrasives from dusts

- brings usable abrasives back for blasting

- collects dust for disposal

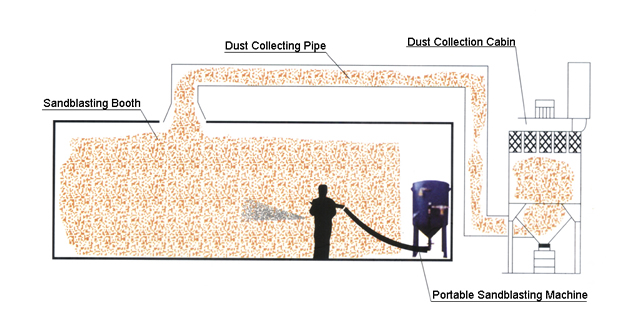

SBM-V and SBM-H series machines come with blasting cabins with recycling and separating units. They are close loop designs and no extra facilities are required for recycling. However, SBM-P portable blasting machine is not equipped with separating and recycling systems. SBM-P is usually applied inside a sandblasting booth. Additional facilities are required for abrasives separating and recycling. There are usually two recycling designs depending on which process is appropriate, automatic or manual.