Features & Specs

- Introduction

- Structure

- Operation

- Options

- Specifications

Options

Loading Table

This table is put next to screen printer. It has tilting arms for glass loading easily.

Inspection Table

Standard outlet conveyor does not come with tilting arms. Optional tilting design and fluorescent lamps are available for inspection.

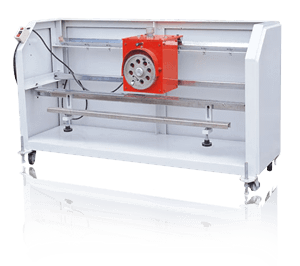

Squeegee Bar Sharpening & Grinding Machine

Ink bars are always in direct contact with screen under high pressure. Screens are usually made of nylon and polyester which are tough. Bars become wear and tear and lose sharpness after operated for some time. They are required to be refurbished. This machine is used to grind the bars until it is recovered to requested sharpness.