Features

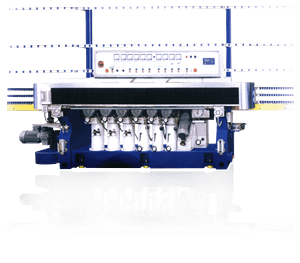

G-VPB-611

Highlights

- 8 spindles G-VPB-611 glass round edging machine produces round edge, OG edge, waterfall & other profile edges

- PLC with HMI touch panel operator interface regulates glass thickness

- Glass working speed adjustable by frequency converter

- Bearing transmission main conveying mechanism

- First two 45o cup wheels remove glass arris heavily reducing subsequent wheels workloads

- Grinding speed is increased while peripheral wheels last longer

- Three polishing wheels obtain fine bright edges

- Pneumatic polishing wheels controlled by PLC

- Mechanical diamond wheel spindles with locking systems

- Up to 700 kg glass loading

- Heavy duty structure weighs 4500 kg

Wheels Configuration

#8 |

#7 |

#6 |

#5 |

#4 |

#3 |

#2 |

#1 |

Positions | |

| Peripheral | Peripheral | Peripheral | Peripheral | Peripheral | Peripheral | Cup | Cup | Forms | |

| CE3 | BK60 | BK46 | Resin Diamond | Resin Diamond | Metal Diamond | Metal Diamond | Metal Diamond | Materials | |

| Polishing | Polishing | Polishing | Fine Grinding | Coarse Grinding | Coarse Grinding | Coarse Seam Grinding | Coarse Seam Grinding | Applications | |

| Φ150 | Φ150 | Φ150 | Φ150 | Φ150 | Φ150 | Φ130 | Φ130 | OD | Sizes (mm) |

| Φ70 | Φ70 | Φ70 | Φ70 | Φ70 | Φ70 | Φ22 | Φ22 | ID | |

| NA | NA | NA | #320 | #230 | #140 | #100 | #100 | Grit | |

| AC 1.5 | AC 2.2 | AC 2.2 | AC 2.2 | AC 2.2 | AC 2.2 | AC 2.2 | AC 2.2 | Motors Power (kW) | |

| Pneumatic | Pneumatic | Pneumatic | Mechanical | Mechanical | Mechanical | Mechanical | Mechanical | Wheels Spindles Feeding | |