Overview

Introduction

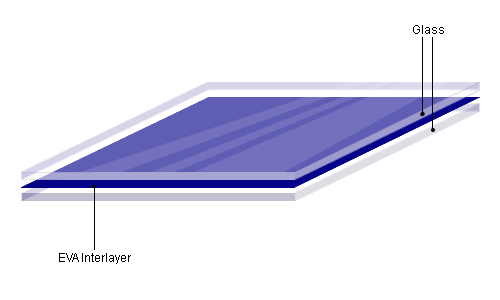

EVA

EVA Film Is A Revolutionary New Type Of Interlayer For Glass And Plastic Sheet Lamination And Encapsulation Without Autoclaving

- EVA stands for ethylene vinyl acetate.

- It is a thermoplastic copolymer resin.

- EVA resin, together with a number of ingredients, is heated and mixed thoroughly and is then extruded through a flat die of a special design plastic extruding machine.

- EVA film is then formed. It is finally wind up in roll for storage and packing.

- Xinology EVA interlayer film contains no plasticizer.

- This extraordinary adhesive film is non-sticky and inert to water moisture.

- Handling and glass assembly could be done under room temperature. No air conditioner and no de-humidifier are required.

EVA Instead of PVB

It Is Proved To Be One Of The Best Alternatives To Costly PVB

- Traditional glass lamination and encapsulation is made by sandwiching PVB interlayer film in between two pieces of glass.

- It is then final bonded with autoclave. EVA glass lamination could be done without autoclave.

- This new type of process requires also no roller press, no vacuum bags and no rubber rings.

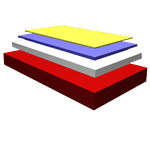

- Similar to PVB, EVA is also sandwiched in between two pieces of glass.

- Thanks to the advance and update technology process, however, production equipments and relevant process for EVA glass lamination is much easier and simple than conventionally PVB lamination.

- Only one single machine is required to fabricate EVA laminated glass.

EVA Becomes Popular

More Glass Fabricators Employ EVA To Be The Priority Interlayer For Glass Lamination And Encapsulation

- As glass design for furnishing, decoration and building becomes more and more sophisticated, versatile glass with better aesthetic visual effect and functions are required drastically at low cost.

- EVA laminated glass meets the requests that simply could not be done or at high cost previously.

- As more designers are well aware the versatility of EVA laminated glass, it is getting more popular.

- EVA laminated glass begins to play significant role for architects, interior and environmental designers.

EVA Classifications

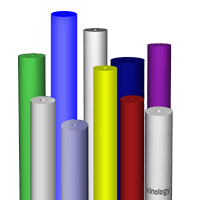

Xinology EVA Film Is Classified In Several Categories

Available in 3 Kinds of Thickness

- 0.25mm

- 0.38mm

- 0.76mm

Available in 30 Colors and Transparencies

- From standard clear to super clear

- From light white to deep white

- From transparent red to transparent black

- From translucent orange to translucent blue

- From opaque yellow to opaque purple

Available For Versatile Applications

- Furnishing, decoration and architectural for both general purpose and outdoor purpose

- Encapsulation for special types of glass such as PDLC smart, intelligent and privacy glass

- Encapsulation for photovoltaic solar panel