Overview

- IG-ED-SA-A

- IG-ED-SA-B

- IG-ED-SA-C-1

- IG-ED-SA-C-2

IG-ED-SA-B

Durable Spindle & Motor

Grinding motor and spindle are made of the best available parts and components.

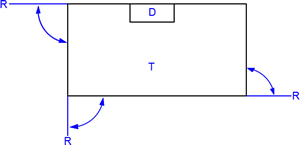

Air Floatation / Suction Table

It is a steel structure with air floatation table on where glass is freely moved. There are guiding rollers at grinding side of the table. It is used to guide glass edges so that glass decoating width is uniform along glass edge.

Flexible Extension Rack

The racks are placed at table sides and are shifted to open for extension when large glass is deleted.

Operation

1. When de-coating small glass, extension racks R are kept at sides of table T. Glass is registered manually with the help of air floating. Then air blower reverses to hold glass in position. De-coating head travels to remove coating all the way along glass edge.

2. When de-coating large glass, extension racks are shifted and extended. Glass is registered manually with the help of air floating. Then air blower reverses to hold glass in position. De-coating head travels to remove coating of part of glass edge. Air floatation helps to move glass manually until next glass edge to be de-coated is registered. Air blower reverses to hold glass in position. Deletion head travels to remove coating of next part of glass edge. Operation procedure described is repeated until all glass edges are de-coated.