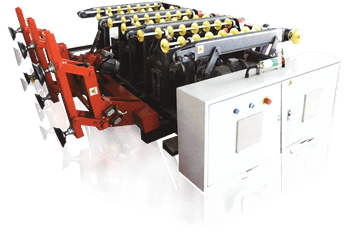

This extra system is identical to first system but it is reversely tilted. This mirror design is helpful if it is required to cut two different glass types, for example, ordinary glass and low-e glass when processing insulating glass. It doubles glass type storages and minimizes glass changeover downtime. This double glass loading machine comes with additional "L" glass racks located next to optional loading arms.

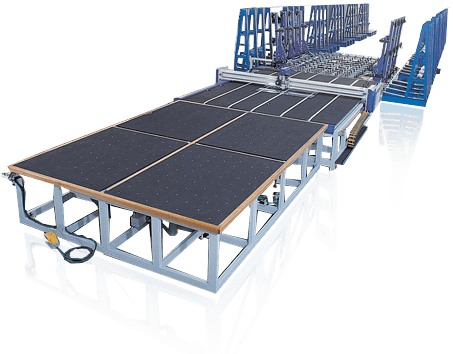

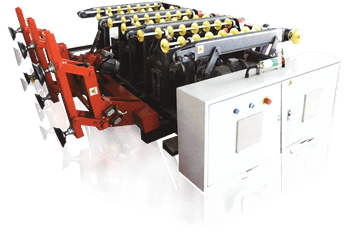

They are traverse belt conveyors locating in between longitudinal roller conveyors. After loading, glass could be transported by conveying rollers downstream to table or conveyor next to loading machine, or by these conveying belts downstream to table or conveyor locating side by side to loading machine. This option provides an alternative for glass traveling direction after loading.

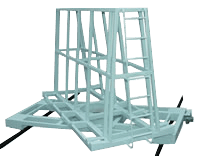

It is a rotating mechanism on which glass rack is put. Instead of "L"-shaped glass rack, optional "A"-shaped glass rack is incorporated with the system. When glass on one side of "A" rack is empty (glass loading) or full (glass unloading), it rotates until another side of glass rack faces to loading machine. While the machine starts immediately to load or unload glass on second side, glass on the first side also begins to be loaded or unloaded. This design minimizes glass changeover downtime.

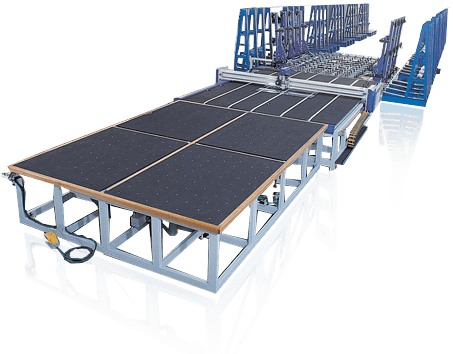

If more glass types are to be loaded, a multi-loading station is required. There are rows of glass racks located upstream of loading machine. Loading machine runs on rail tracks and stops at right glass rack which is pre-set. If necessary, two rows of glass racks are designed opposite to each other along rail tracks. This design is to have more glass types for selection. A double-sides loading machine is always incorporated to this two rows design of glass racks. The control system and program are upgraded such that the machine is pre-set so that it knows the sequential order of glass picking up from racks. This multi-loading station is also a glass storage system and the sophisticated design greatly reduces glass changeover downtime.