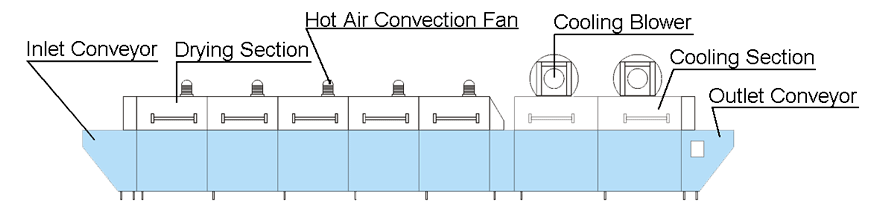

Features

Structure

Inlet Section

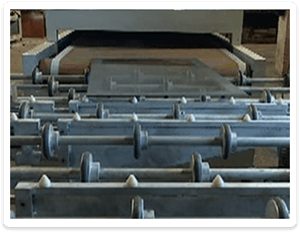

It is belt conveyor or roller conveyor design. Those parts of conveyor, which get in direct contact with glass, are heat resistant and are non scratch to glass.

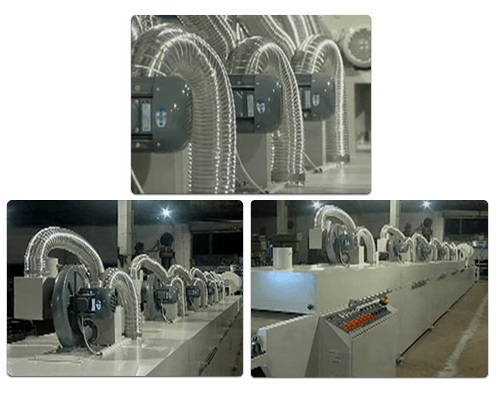

Drying Section

It is equipped with heating element which are used to heat up and dry ink. There are thermocouples which are used to measure real time temperatures. Glass travel speed is adjusted by infinite speed regulator. Oven wall are well preserved with high quality thermal insulation materials. There is hot air convection fan installed at top of oven. It generates air convection inside the oven. This gives consistent environmental temperature so that ink is dried at adequate conditions. During drying, thinner or solvent is vaporized from ink. Exhaust pipes are provided above oven to certain length. Unwanted vapor is evacuated through exhaust pipe. It is finally removed out of workshop. Exhaust pipes leading vaporized gas out of workshop are to be provided by buyer. Length of drying oven is depend on ink drying temperature, ink drying time, glass length and requested production capacity.

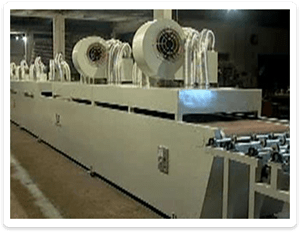

Cooling Section

It is equipped with air cooling blowers to cool down glass until it is cool enough for handling during unloading.

Outlet Conveyor

It is belt conveyor or roller conveyor design. Those parts of conveyor, which get in direct contact with glass, are heat resistant and are non scratch to glass.

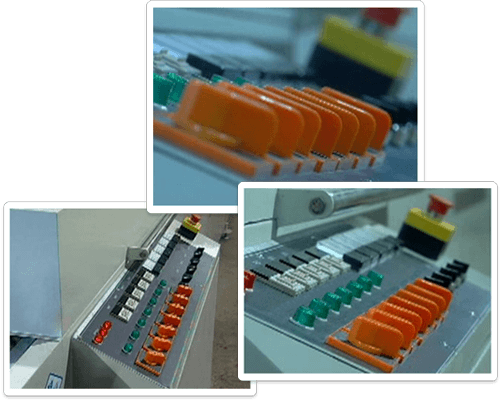

Control Console

All operations of the oven are accessed from this control console.