Overview

Thickness & Weight

Simply speaking, the thicker the glass and plastic film, the more safety it is. However, a capable armour glass manufacturer could design a lighter and thinner sheet of bullet proof glass to stop AK47 bullet while an inexperience manufacturer uses thicker and heavier sheet of bullet resistant glass to stop the same bullet.

Two sheets of armour glass with equal total thickness could be made from different thickness of several pieces of monolithic glass. For example, there are two sheet of armour glass with two different configurations but with same total thickness, say 50mm. One of the armour glass is made out of three pieces of 15mm glass with approximately 5mm total plastic film thickness. Another is made out of three pieces of 12mm glass, one piece of 10mm glass and 4mm total plastic film thickness. Although they have equal total thickness 50mm, one of the armour glass could fulfill certain application while another could not. Moreover, for the second armour glass, the 10mm glass put in first layer, inner layer or final layer may result in different outcomes.

Generally speaking, all armor glass designers are targeting to reduce the thickness and weight of armour glass and meanwhile, remain its characteristics unchanged or even better. After all, customers would rather prefer less expansive, thinner and lighter armour glass especially armour vehicles owners who concern safety on one hand but also fuel energy on the other. Calculation, trial and test are required to find out thinner and lighter configurations of armour glass to accomplish same task that thicker and heavier armour glass is required before. This technology know-how is the heart of a well experience armor glass manufacturer.

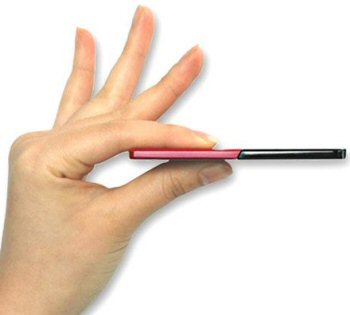

Some designers has already begun to use thin chemically strengthen glass as one of the composition of armour glass to reduce the thickness and weight drastically. The chemically strengthen glass could be 2mm or even 1mm and less. Chemically strengthen glass is few times tougher than thermally tempered glass. 1mm or thinner chemical strength glass is flexible, while tough, and could be bent with conventional curve glass at room temperature. This feature allows versatile applications of armor glass and is began more popular by armour glass designers.