Overview

Introduction

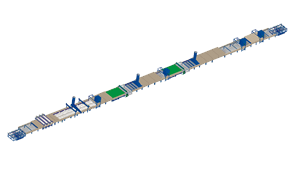

Xinology SM Series Silver Mirror Production Line Produces Top Quality Silver Mirror At Lowest Possible Cost

There are several ways to turn glass into mirror. Mirrors are obtained when reflective metals deposit on glass. The most popular metals are silver, aluminum and chromium, etc. Most of the mirrors around us everyday are made of silvering process. Xinology SM series mirror silvering conveyors are designed for industrial mass production of silver mirror.

Silver plating principle of SM series mirror silvering conveyor makes use of high performance deoxidization to deposit thin silver and copper films on flat glass. Lastly, mirror back paints are applied on top of silver and copper films.

Principle

Silver Metal Molecules Are Reduced From Silver Ions Solution By Reducing Agent & Deposit On Glass Surface

Silver plating reaction is carried out between silver ion solution and glucose, fructose or formaldehyde solution which is also know as reducing agent or reducer. Silver nitrate is usually used as source of silver ion. Oxidation of carbon occurred when silver ion is reduced. During the reaction, silver ions are reduced to silver molecules and adhere to glass. Formation of silver metal is due to reduction of silver ion.

It is a redox (reduction and oxidation) reaction with selective organic substances. One substance loses electrons while another substance gains electrons.

- Substance that loses electrons is said to be oxidized. This substance is so called reducing agent or reducer.

- Substance that gains electrons is said to be reduced. This substance is so called oxidization agent.

In silver coating, glucose, fructose or formaldehyde solution is known as reducing agent or reducer. Silver nitrate is known as oxidation agent.

Develop

Mirrors Have Been Developed For Hundreds of Years

Many years ago, mercury was used in certain glassware when reflective effect was required. At that time, mirror was also known as mercury glass. Nowadays, mirrors are generally made of

- silvering process by depositing silver on glass

- aluminum or chromium deposited on glass by evaporation under vacuum

- aluminium or chromium deposited on glass by magnetron sputtering under vacuum

Glass Scrubbing & Washing

Industrial Production Of SM Series Mirror Silvering Conveyor Consists Of Quite A Number Of Processes

Glass Scrubbing & Washing

Clean glass is one of the most critical point to obtain top quality mirror.

Glass Warming Up

Silvering process performs well when glass is at about 30℃. Therefore, glass is warm up with heated water.

Sensitizing Tinning

Glass surface is needed to be sensitized before silvering. The sensitized material is usually tin ions solution.

Silvering

Silver ion solutions and reducing agents are meter, mixed and spray on glass. Silver ions are reduced to silver metal molecules depositing on glass.

Coppering

Copper ion solutions and reducing agents are meter, mixed and spray on glass. Copper ions are reduced to copper metal molecules depositing on glass. Copper is used for fragile silver layer protection.

Blowing & Drying

Excessive chemical solutions are blown off. Excessive water is then dried by force air.

Mirror Back Painting

Mirrors are then further protected and enhanced by painting with opaque paint. Painting prevents from physical contacts and chemical corrosions. Light reflection is brighter because the paint reduces further the light passing the silver coating. It could be one or two paint layers depending on requests.

Drying & Curing

Paints are then dried and cured at high temperature. Heating speeds up curing process and provides smooth paint surface which optically looks better.

Acid Washing

Acid is used to remove silver, copper and paint residues left on mirror front surface during preceding processes.

Final Washing & Drying

Mirror is then thoroughly washed by water and is air dried prior to packing.

Paint Layers

Few factors are to be considered when deciding to use one or two layers of paint

Standards

There are several well known international mirror standards. Some of them do not mention how many layers of paint are required as long as mirror samples pass all the tests such as salt spray test. Some standards mention two layers of paint are required. These standards maybe issued some years ago when paint quality did not perform very well for protection. So the standards requested compulsory two layers of paint for better protection. However, paint quality becomes better as chemical industry is developing. Nowadays, one layer of excellent quality of paint may meet all tests including salt spray test. Hence, when it is requested to meet those standards which do not mention how many paint layers are required, single layer of excellent quality of paint layer maybe good enough.

Paint Quality

If paint quality is not good quality, double layers of paint maybe required. If excellent quality of paint is employ, single paint layer maybe good enough to meet all kinds of test.

Customer Request

Requested standard does not mention how many of paint layers are required. Single layer of paint may meet all kinds of test. However, some customers may feel comfortable or competitive if mirror has two layers of paint.

Glass of Mirror

Silvering Is Always Done On Excellent Quality Of Glass

If it is flat glass, float glass is always employed. If glass is flaw, the defects become more obvious after mirroring. Sometimes, sheet glass is used for thin mirror, for example 1 or 2mm. This is always applied in tiny mirrors such as hand carry cosmetic mirrors. When mirror is small, flaw or wave is not quite obvious.

Mirror Edge Protection

Mirror Edge Protection Paint Prevents Chemical Corrision From Edge Attack

Silver may be exposed at mirror edge if process is improperly done. Corrosion may attack and spread from edge to inner side. If it is necessary, chemical agent is added on mirror edges for anti-corrosive protection.

"L" & "U" Layout

Layout Of SM Series Could Be Designed In Straight, L or U Shape

SM series silver mirror production is generally design in a straight line. If necessary, for example, limited of workshop space, the line could be designed in L-shape or U-shape.