Features

General

Glass travels vertically at almost 90 degree on washing machine. It always leans against on vertical idle rollers conveyors all the way from the inlet conveyor till exit conveyor. There are bottom rollers where glass bottom edge lies on. There bottom rollers drives the glass from inlet conveyor to exit conveyor. All rollers are anti-acid and scratch-free. No marks are left on glass. The machine is composed of following sections.

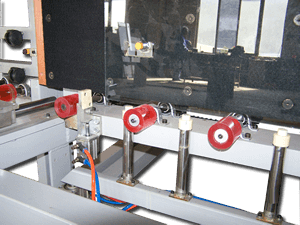

Inlet Conveyor

This conveyor consists of two parts. The first part is a vertical rack with idle rollers where glass is almost vertically lean on. The second part is bottom rollers where glass bottom edge lies on. The bottom rollers are powered by electric motor and drive the glass into subsequent washing section in vertical position.

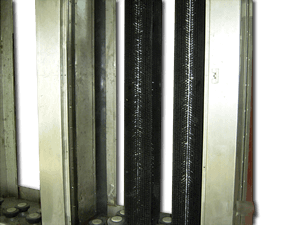

Cylindrical Brushes Washing Section

This system consists of pairs of cylindrical brushes and water pipes. There are one top brush and one bottom brush for each pair of cylindrical brush. Glass passes in between top and bottom brushes. Top and bottom glass surfaces are thoroughly cleaned. The brush filament is carefully selected such that it leaves no marks on glass while strong enough to remove all kinds of dirt, grease and dust, etc. All parts and components are made of stainless steel or rust-proof materials. There are access doors with window. The door could be unlocked and opened for maintenance. Visual observation during operation is achieved through the window.

Rinsing Section

After cylindrical brushing, glass then travels to rinsing section where there are water pipes to rinse the glass thoroughly until there are no more residual or contamination on glass surfaces. All parts and components are made of stainless steel or rust-proof materials. There are access doors with window. The door could be unlocked and opened for maintenance. Visual observation during operation is achieved through the window.

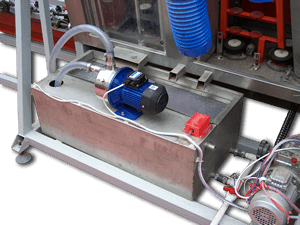

Water Recirculation System

Water is pumped from stainless steel water tank and is then spray on brushes through water pipes with sprinkle. The water is evenly distributed on brushes and is spread on glass thoroughly. Water drips down to water tank by means of water collectors. There are water filters to keep water clean so that pipes and nozzles are unblocked.

Drying Section

After glass leaves rinsing section, it immediately enters into drying section. Pairs of air knives are put vertically and are inclined at certain angle to glass travel direction. There are narrow openings on each of air knives. Drying air with optimum quantity and pressure is blown on front and rear glass surface. The water is thoroughly dried.

Air Blower

An air blower is located behind washing machine. It is enclosed inside a sound-proof box for acoustic purpose. The air blower generates appropriate quantity of air at proper air pressure. The air flows through air ducts and arrives at air knives. There are filters to ensure inlet air blown on glass is clean and free of contamination on glass.

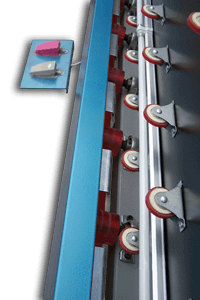

Inspection & Outlet Conveyor

After glass leaves drying section, it exits on this inspection and outlet roller conveyor. This rollers conveyor is similar to inlet conveyor but with additional fluorescent lamps located at the back of glass. This is used to inspect if the glass is clean enough for downstream processes, for example, double glazing.

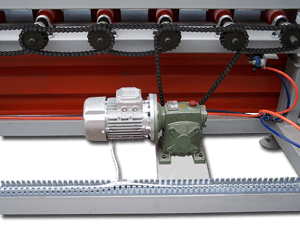

Driven Mechanism

The bottom rollers from inlet conveyor till outlet conveyor are all steadily driven electrically by infinite reduction gear motor. The high quality parts and components guarantee consistent movement of all rollers. Top and bottom cylindrical brushes are driven electrically by reliable motor working 24/7.