Features

Bending & Tempering

Transverse Bending

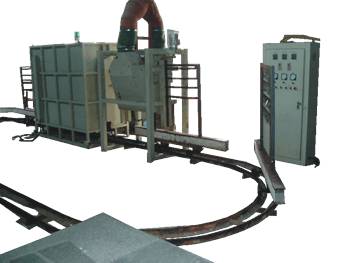

GTF-(FTB)-(xxxx+xx)-1

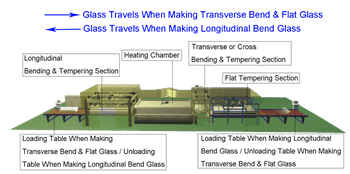

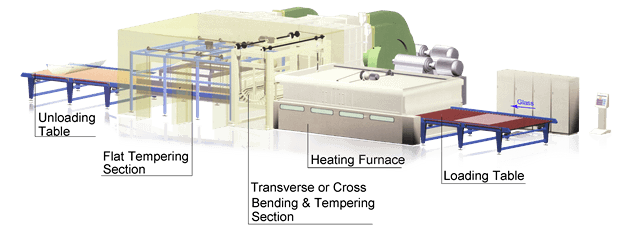

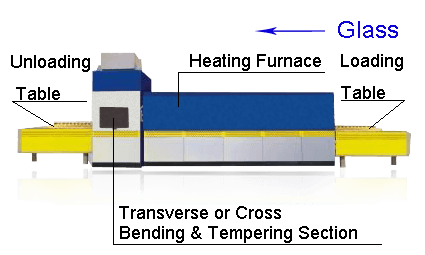

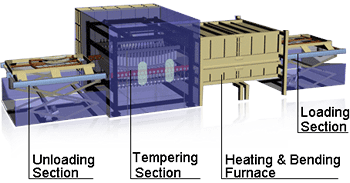

Horizontal Transverse/Cross Glass Bending & Tempering Furnace with Flat Glass Tempering Section

Structure

It is a rollers bending system to produce single curvature of glass. It can produce glass sizes from large to small. It can produce glass curvatures from large to small. The rollers are part of the conveying system of glass tempering furnace. Bending curve is in glass travel direction and so it is known as transverse or sometimes, cross bending. There is a lifting system to lift up rollers to form a curvature with certain bending angle. Various radius of curvature could be obtained from different rollers lifting levels creating corresponding bending angles. Quenching plenums are incorporated to rollers bending system such that there is one plenum in between every two rollers.

Universal Transverse Bending & Tempering System for Medium Large Glass Sizes

with Medium Large Glass Curvatures

Universal Transverse Bending & Tempering System for Medium Small Glass Sizes

with Small Medium Glass Curvatures

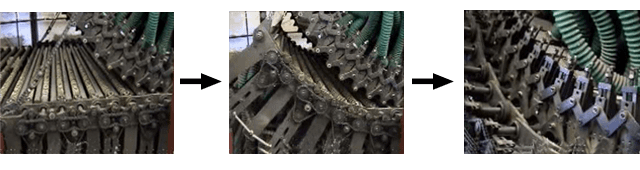

Lower Part of Bending Section Lifted up & Curve Hot Glass into required Radius of Curvature

Procedure

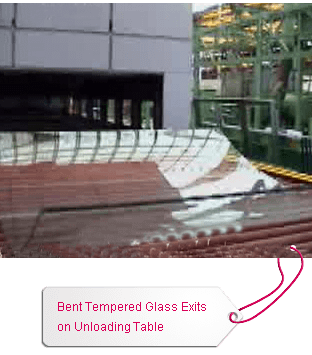

Glass exits from heating section onto this rollers bending system with all rollers in same level to ceramic rollers of heating section. Glass stops at roller bending section. Lifting system lifts up rollers until requested bending angle is reached. The rollers start to rotate to bring glass to and fro within the leading edge and tailing edge of the bending section until requested glass curvature is obtained. Blowers immediately quench the glass until it is tempered. Lifting system lowers down all rollers until they are level with subsequent cooling section's rollers. Glass then travels to cooling section.

Summary

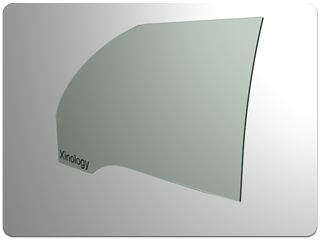

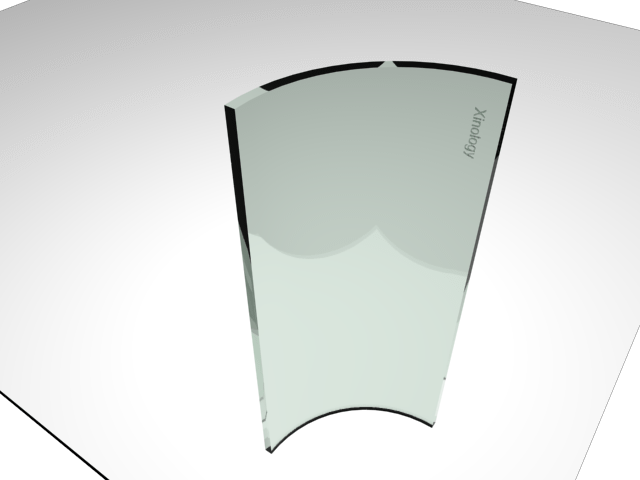

This technology is suitable to produce automotive sidelites, ventilators, shower doors, furniture, household glass and glass for electrical appliances, decorative glass and architectural glass, etc.

GTF-(TB)-(xxxx+xx)-1

Transverse Bending & Tempering Furnace without Large Flat Glass Tempering Section (This furnace produces also small flat tempered glass.)

Longitudinal Curve Bending

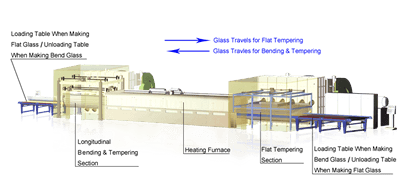

GTF-(LB)-(xxxx+xx)-1

Longitudinal Curve Bending & Tempering Furnace for Single Curvature of Glass & Produces also Flat Tempered Glass.

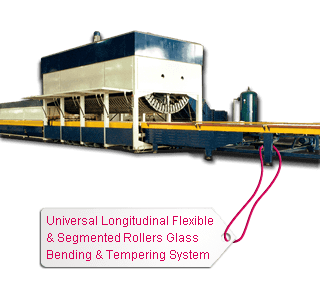

Structure

It is a roller bending system to produce single curvature of glass. Unlike transverse bending, the rollers are segmented designed for curving into various curvatures. Bending curve is perpendicular to glass travel direction and so it is known as longitudinal bending. There is a lifting system to lift up bending rollers. Due to segmented design, bending rollers lift up above conveying rollers to form a curvature with certain bending angle. Various radius of curvature could be obtained from different rollers lifting levels creating corresponding bending angles. Quenching plenums are incorporated to rollers bending system such that there is one plenum in between every two rollers. Like bending rollers, quenching plenums are also segmented.

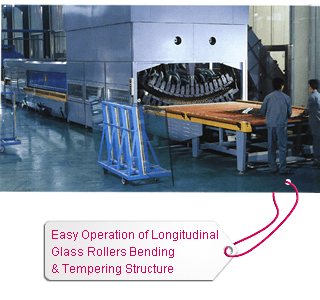

Procedure

Glass exits from heating section onto conveying rollers of bending and tempering section with all segmented bending rollers beneath conveying rollers. Glass stops at proper position on bending and tempering section. Lifting system lifts up segmented rollers until they are above conveying rollers and requested bending angle is reached. The segmented rollers start to rotate to bring glass to and fro within side edges of the bending section until requested glass curvature is obtained. Oscillating direction during glass curvature forming is perpendicular to glass conveying direction. Blowers immediately quench the glass until it is tempered and cooled. Lifting system lowers down all segmented rollers until they are beneath conveying rollers. Bent and toughened glass is then supported by conveying rollers which eventually brings glass to unloading section.

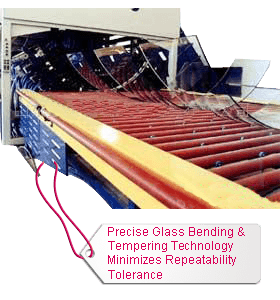

Summary

This technology is suitable to produce medium large bent tempered glass with medium large radius of curvature such as architectural glass, decorative glass, furnishing glass and glass for kitchenware, etc. Flat tempered glass can also be produced from this segmented roller bending system when all rollers are extended to flat status. Since rollers distances are slightly large, thick flat glass and/or small sizes of flat glass are recommended to be produced from this section. V shape bent tempered glass could also be made from this technology with a modified segmented rollers bending mechanical structure.

GTF-(F+LB)-(xxxx+xx)-1

Two Directions Glass Tempering Furnace with an Extra Flat Glass Tempering Section

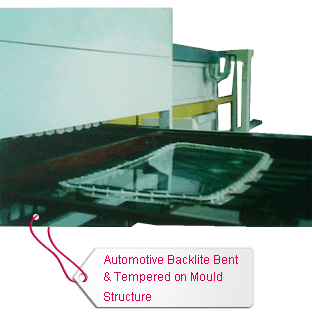

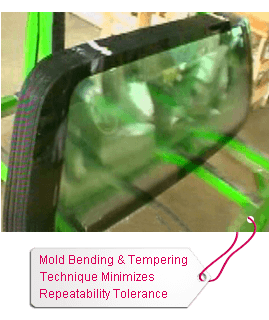

Mould Bending

Compound bent tempered glass with double or complex radius of curvature could not be, for the time being, made from rollers bending mechanism. Instead, moulds are required. Moulds are usually non adjustable to suit different shapes of bent tempered glass. Thus, one type of bent glass requires one mould. Moulds are usually made of metal or ceramic. Quenching plenum is also specially design to conform glass shape. With sophisticated engineering, some quenching plenums could suit a series of bent glass within certain range of radius of curvature. This technology is often used to make automotive glass such as backlites, sidelites and ventilators with double curvatures or any other bent tempered glass with compound or complex radius of curvature.

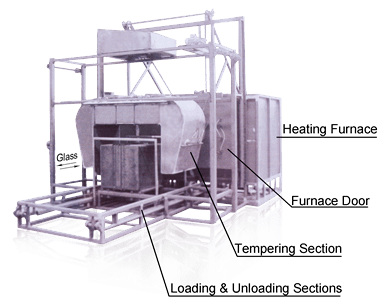

GTF-(MB)-(xxxx)

Compound & Complex Glass Bending & Tempering Furnace

Right Angles Bending

It is used to produce U and L shapes of glass. Glass is usually bent with a mould. The two extended glass surfaces of the right angle are usually flat. So the mould is simple and is universal to any kind of right angle bent glass with any sizes.

GTF-(RAB)-(xxxx)

Right Angles Glass Bending & Tempering Furnace

Vertical Bending

Glass travels vertically in a vertical bending and tempering furnace. This furnace produces bend tempered glass absolutely optical distortion free. Tong marks are found on top edges of glass due to hot glass hanging by tongs during handling.

GTF-(VB)-(xxxx)-1

Vertical Glass Bending & Tempering Furnace