Features & Specs

Operation

The heating and tempering programs are made according to the operator’s (in the first time by Ianua’s installation supervisor’s) experience, depending on glass thickness, on glass type (normal float, tinted glass, reflective glass etc.), on loading (large glass or many small glasses) etc. To control the amount and the relation top/bottom of the convection heating, a “teach in” -system is used (“teach in” = operator’s manual control is memorised in the recipe file of the computer). This first introduction of a recipe is made only once for each type of glass and it can be called by given name whenever wanted for the same glass and loading type, and the control system will run the furnace automatically, without any manual control or adjustment.

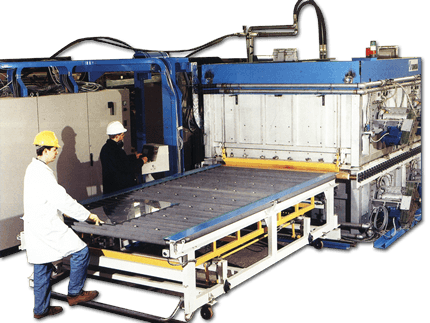

After the glasses have been loaded on the loading table with help of the intermittent drive system, if desired, the load and its recipe are acknowledged by the push button “Loading Ready”, and after that the load is automatically transported to the photoelectric switch to wait to be entered into the furnace. When the previous load has left the furnace, the acknowledged load is transferred inside without any delay. Also the rest of the process is automatically controlled, according to the parameters of the recipe.

The operator follows the glass behaviour in the furnace and checks the tempering result. If necessary, he makes the needed adjustments. When the glasses have been cooled down, the other operator unloads them so that the unloading table will be free for the next load.