Overview

Standard

Introduction

This standard prescribes chemical strengthen glass term and definition, classification and sign, technical requirement, testing method, inspection ruler, packing, indicating, transportation and storage.

Quoted Documents

Below documents terms through this standard quoted become this standard's clause. Every quoted document which indicated date, its subsequent all amendment clause (Not included an error content in printing) or revised edition are not suitable for this standard.

- GB/T 1216 External Diameter Micrometer

- GB/T 5137.1 - 2002 Auto Safety Glass Testing Method (1st Section: Mechanics Test)

- GB 11614 - 1999 Float Glass

- GB/T 18144 Glass Stress Testing Method

- JB/T 8788 Clearance Gauge

Terms & Definitions

Below terms and definitions are suitable for this standard.

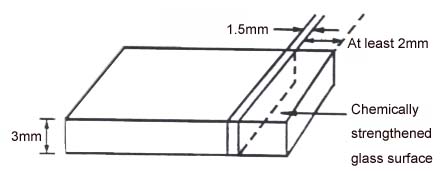

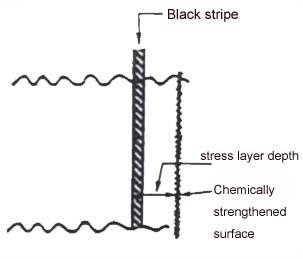

Chemically Strengthened Glass is process through ion exchanged, alkali metal ions in the glass surface have been replaced by the other metal ion in molten salt, it will improve glass mechanical strength.

Sign, Packing, Storage & Transportation

SIGN

In each packing box it should be mark product sort, thickness, company name and brand, standard code and product sign, still give clear indication of "lightly put, moisture resistance, upwards".

PACKAGE

Product should be packed by wooden case or other package box, glass should be vertically put in box, in each piece of glass it has plastic cloth or paper packed, between glass and package case it should use light and soft material to fill the space, in this way it will avoid scratching

STORAGE

Product should be put vertically in dry room.

TRANSPORTATION

In transportation, do not put wooden case flat, packing length should be the same as vehicle moving direction, have rainproof measure in transportation.

Appendix B(Chemically Strengthening Glass Relevant Specification)

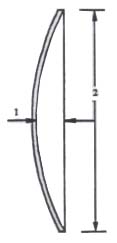

- Chemically strengthened glass is reinforcing glass got through ion replacement. Ion replacement procedure can effectively improve glass mechanical strength, and especially suit for reinforcing ultrathin, small size or complex shape glass product. Glass through ion replacement processing do not produce obvious optics distortion.

- Chemically strengthened glass strength has relative with glass component, surface and edge state, ion replacement procedure processing and usage surroundings etc factor.

- Though chemically strengthened glass surface compressive stress is very high, the center glass tensile stress which is opposite with surface compressive stress is very low, so chemically strengthened glass do not exist in spontaneous explosion phenomenon.

- Chemically strengthened glass should be keep a certain replacement layer depth, The more time replacement need, the more depth replacement layer will be exist in, but surface stress will reach crest, then reduce gradually.

- If single normal anneal glass through ion replacement make chemically strengthened glass is not safety glass, its fragment state after ruptured is similar with broken state of normal anneal glass. When it use in some place that will affect personal safety, it need to process more, such as to make laminated glass.

- Chemically strengthened glass can be cut, but new cut edge will reduce intensity, so to give producer suggestion, it is better to finish all of pre-process procedure before Chemically strengthen.

- Ion replacement procedure changed glass surface character, therefore, chemically strengthened glass subsequent processing (eg. laminated glass or coated glass) procedure is different with processing non- chemically strengthened glass.