Features & Specs

BD

It is compose of high molecular material with a mixture of aluminium oxide and silicon carbide etc. The high molecular material is carefully selected such that the wheel is high elastic but meanwhile, with super wearability and high strength. The metal compounds allow super cutting ability.

The elasticity allows the wheel in full contact with the whole glass edge giving thoroughly polishing but meanwhile, allowing easy discharging of polishing scrap leaving no flaw on glass. It could also reduce pressing pressure and thus, avoiding burning.

Thanks to its rigidity, the shape shall not deform nor crack despite of glass edge cutting defect, machine vibration and improper operation. The fine powder gives excellent bright satin finish.

The common edge processing is to use firstly metal bond diamond wheel, then secondly resin bond diamond wheel and finally BD wheel.

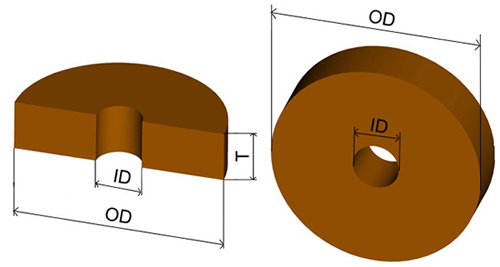

Specifications

| Item | OD | ID | T |

| BDA OD/ID/T | |||

| BDA 150/22/15 | 150 | 22 | 15 |

| BDA 150/22/20 | 150 | 22 | 20 |

| BDA 150/22/25 | 150 | 22 | 25 |

| BDA 150/22/30 | 150 | 22 | 30 |

| BDA 150/25/15 | 150 | 25 | 15 |

| BDA 150/25/20 | 150 | 25 | 20 |

| BDA 150/25/25 | 150 | 25 | 25 |

| BDA 150/25/30 | 150 | 25 | 30 |

| BDA 200/90/15 | 200 | 90 | 15 |

| BDA 200/90/20 | 200 | 90 | 20 |

| BDA 200/90/25 | 200 | 90 | 25 |

| BDA 200/90/30 | 200 | 90 | 30 |

| Item | OD | ID | T |

| BDB OD/ID/T | |||

| BDB 100/22/15 | 100 | 22 | 15 |

| BDB 100/22/20 | 100 | 22 | 20 |

| BDB 100/22/25 | 100 | 22 | 25 |

| BDB 100/22/30 | 100 | 22 | 30 |

| BDB 150/22/15 | 150 | 22 | 15 |

| BDB 150/22/20 | 150 | 22 | 20 |

| BDB 150/22/25 | 150 | 22 | 25 |

| BDB 150/22/30 | 150 | 22 | 30 |

| BDB 150/25/15 | 150 | 25 | 15 |

| BDB 150/25/20 | 150 | 25 | 20 |

| BDB 150/25/25 | 150 | 25 | 25 |

| BDB 150/25/30 | 150 | 25 | 30 |