Features & Specs

Solar Cell Assembly & Soldering

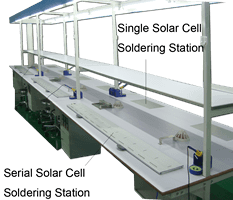

Solar Cell Assembly & Soldering Table

- It is a working table where solar cells are singly or serially soldered.

- The process includes tabbing, stringing and interconnecting.

- The table is made of steel or aluminum alloy structure.

- The table comes with a 125 and a 156 cell soldering fixture.

- The table is equipped with high quality and durable carbon fiber heating device which increases temperature rapidly.

- Temperature is controlled and freely adjusted by PID allowing uniform heating.

- The table consists of several working section for several operators and each operator can works independently.

- There are lighting allowing operators focusing on their jobs.

- Safety power supply attached to working table.

| Structure | Steel and/or Aluminum Alloy Structure |

| Temperature Control | PID |

| Outer Dimension (LxWxH) | 2100 x 1200 x 1800 mm |

Single Solar Cell Heating Device

- This devise is to preheat single solar cell prior to soldering.

- Heat up solar cell gradually to reduce heat stress during soldering.

- Consistent temperature of top and bottom surfaces of solar cell.

- Minimizes soldering defect and thus, maximizes soldering production yield.

- The heat silicon rubber plate is laminated with oxidized aluminum sheet.

- High Precision PID temperature heating control.

- Uniform heating and heat dissipation.

- Heating and also dehumidifying.

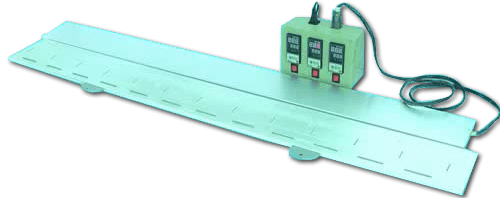

Serial Solar Cells Heating Device

- This devise is to preheat serial solar cell prior to soldering.

- Heat up solar cell gradually to reduce heat stress during soldering.

- Consistent temperature of top and bottom surfaces of solar cell.

- Minimizes soldering defect and thus, maximizes soldering production yield.

- The heat silicon rubber plate is laminated with oxidized aluminum sheet.

- High Precision PID temperature heating control.

- Uniform heating and heat dissipation.

- Heating and also dehumidifying.