Overview

Introduction

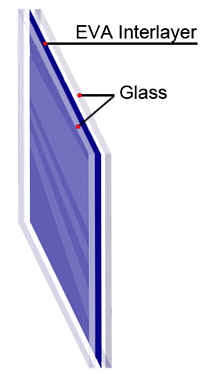

Traditional laminated glass is made out of PVB interlayer film. It is final bonded with autoclave. After years of research, a new type of glass laminating technology, free of autoclave, is developed. No autoclave and no roller press are required. No vacuum bags and no rubber rings are required. No climatic control room is required. Instead of PVB, thermo-plastic films are employed for autoclave free laminated glass production. EVA interlayer, made of ethyl vinyl acetate copolymer resin, is the most popular plastic film for laminated glass production free of autoclave. EVA laminated glass and its production has a number of advantages against PVB’s.

All materials, including glass and EVA film, are lay up and well assembled. It is then put inside the oven for heating under vacuum. The EVA becomes melted and bond the glass.