Overview

- Advantages of EVA Laminated Glass

- Advantages of EVA Laminated Glass Production

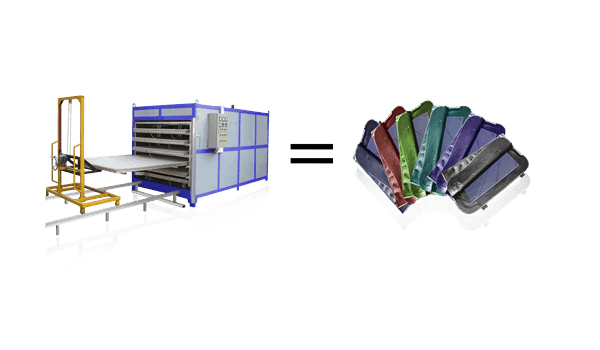

Advantages of EVA Laminated Glass Production

Less Capital Investment

Only one single machine is required to produce EVA laminated glass. It is just an oven. No investment in autoclave is required. No investment in large pre-laminating line is required.

No Vacuum Bags and No Rubber Rings

High temperature resistant silicon vacuum pads are incorporated with EVA laminating oven. Well assembly glass is put inside the silicon pad which sealed tight to prevent air leaking during vacuum. No extra vacuum bags or rubber rings are required.

No Rollers Presses and No Autoclave

Thanks to years of research and development and proven experience as well, EVA laminated glass could be obtained without using autoclaves nor rollers presses. The EVA laminating production done by proper vacuum and heating oven is a one step process. Pre-laminating and final bonding are done within the same oven.

Durable & Flexible Silicon Blankets

This strong silicon pad meets the most severe industrial tests. It is made of special high temperature resistant silicon. The material would not become brittle after numerous heating up and cooling down. It resists to high tearing force when warping around glass during vacuum.

Patented Silicon Blankets Edge Seal

Top and bottom pad edges are specially designed providing air-leak proof interlocking system. The higher the vacuum in between top and bottom pads, the firmly the edges are seal.

Fast & Easy Glass Loading & Unloading

Thanks to silicon pad edges sealing design, it is firmly sealed on one hand while it could be unseal and open easily on the other. This allows fast glass loading and unloading resulting in high production efficiency.

Non-Restricted Glass Sizes & Shapes

Extraordinary high tensile strength and elongation of silicon pads allowing different sizes of laminated glass loaded in same silicon pads and within one batch.

High Vacuum

When top silicon pad wraps around laminated glass, there is no room for any air trapped between top and bottom silicon pads. This is due to powerful vacuum pump, highly flexible silicon pad and patented silicon pad edges sealing.

High Production Capacity

EVA glass laminating oven comes with a multi-storey rack with several sets silicon pads. If glass is small enough, each silicon pad could hold few pieces of glass at one time. Many pieces of laminated glass could be made in one batch especially when all silicon pads are fully loaded with glass.

Fast Production Cycle

Thanks to powerful hot air fan blower, forced convection heating is created to provide high efficient heating profile resulting short production cycle.

Double Productivity

Standard oven comes with one glass rack. With an optional extra glass rack, well assembled glass could be prepared and loaded while standard rack is processed inside oven. When standard rack is done and pulled out from oven, extra loaded rack is put inside the oven for immediate heating. Glass is unloaded and loaded in standard glass rack. This extra glass rack doubles the capacity without any extra oven. The oven is fully utilized with the least idle time.

Safe Equipment

Not like autoclave, EVA laminating oven is not a pressure vessel.

Less Space

EVA laminating oven is comparatively small and occupies little space.

No Foundation

Not like autoclave, EVA glass laminating oven requires no pit or slot.

No Climatic Control Room

EVA is stored, handled and laminated under room temperature. No climatic control room is required.

No Air Conditioner or Dehumidifier

EVA is almost inert to water moisture. It requires no air conditioning and de-humidifying.

Easy Operate

EVA glass laminating oven comes with a PLC where only temperature and time parameters are required to be input. The oven will run itself until EVA laminated glass is done. It is just that simple.

Maximize Labor Efficiency

When first batch is heated and cooled inside oven, operator is not required to look after the oven. He could be switched to process interlayer cutting and glass assembly for next batch.

Less Labor Forces

If glass is not large, one operator is enough to assembly glass and handle the EVA laminating oven.

Low Power Consumption

EVA laminated glass consumes less than 1.2 kW/m2 calculated base on 5+5mm glass with 90% loadings.

Low Operating and Maintenance Costs

Operating cost could be minimized when all silicon pads are fully loaded with glass at one batch. The oven is design in simple construction and requires very little maintenance.